Polyethylene terephthalate (PET) is a chemically stable polyester. It finds use in a multitude of applications such as plastic bottles, containers, electronic and automotive components and packaging films because of its cost and durability. In this article, let’s delve into a list of polyethylene terephthalate products to explore its wide range of uses in many industries and daily life.

1. Overview of polyethylene terephthalate (PET)

Polyethylene terephthalate, commonly known as Polyethylene terephthalate PET or PET for short, is a type of thermoplastic polyester resin. It is produced by chemically reacting purified terephthalic acid (PTA) with ethylene glycol (EG). This process results in the formation of a linear polymer with distinct properties and characteristics.

Polyethylene terephthalate (PET) possesses a wide range of properties that make it highly sought after in various industries. It includes transparency, strength and durability, lightweight, chemical resistance, thermal stability, recyclability, good gas (oxygen, carbon dioxide) and moisture barrier, etc.

PET can be processed using a common molding method such as injection molding, blown molding and extrusion. This material is also suitable to be applied for fabricating thin layer products like stretched film and thermoforming.

Read more: What is Polyethylene terephthalate (PET)?

2. A list of polyethylene terephthalate products

Polyethylene terephthalate finds extensive use across various industries due to its exceptional properties and versatility. Let’s explore some of the common polyethylene terephthalate products below:

2.1. Packaging products

Polyethylene terephthalate’s transparency, lightweight nature, and excellent barrier properties make it ideal for packaging beverages, food, personal care products, medical and pharmaceuticals. Here are some polyethylene terephthalate products commonly in that area:

- Plastic bottles: Beverage bottles (soft drink bottles, juice bottles, water bottles), personal care bottles (cosmetic bottles, shampoo or conditioner bottles, liquid hand soap bottles), household product bottles (cleaning agents, detergents), food bottles (edible oils, sauces), etc.

- Food containers: Microwaveable or fast-food containers, carry-home food containers, fresh food trays, etc.

- Packaging films: Stretch films, shrink wraps, laminated films for flexible packaging, etc.

- Adhesive tapes

- Blister packs

2.2. Textiles and apparel products

PET uses come in different forms in the textile industry. Polyester fabrics are firm, flexible and prevent shrinkage compared to cotton. In addition, PET fibers are lightweight, crease and tear resistant, which enables the production of quality products. You can see that material in some polyethylene terephthalate products such as:

- Clothes, including everyday wear, sportswear, and activewear.

- Home textiles such as bed linens, curtains, and upholstery fabrics.

- Outdoor gear such as tents, backpacks, and outdoor clothing.

- Industrial fabrics such as conveyor belts, filter fabrics, and mesh screens.

2.3. Electrical and electronics products

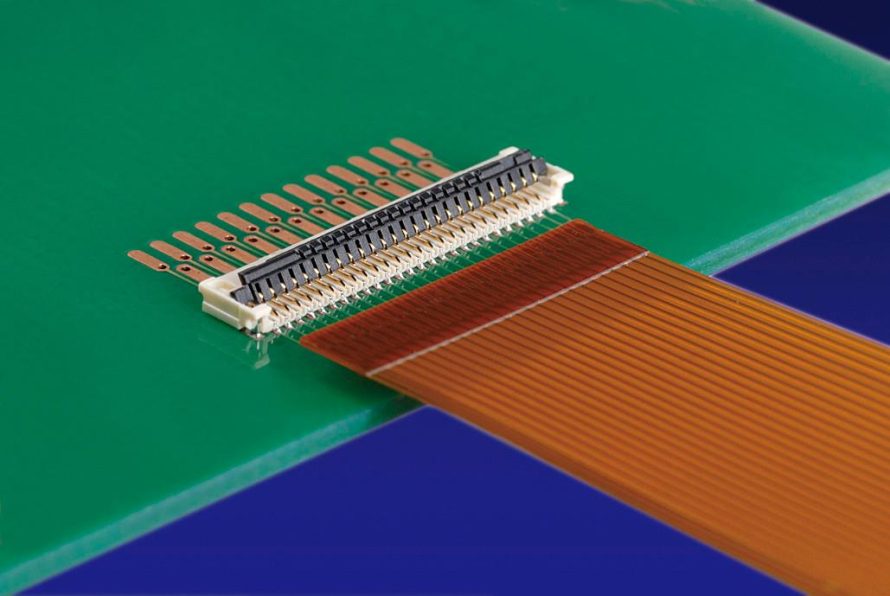

Due to its thermal stability, high dielectric strength and resistance to heat, PET is employed in various electrical and electronic applications. Electrical and electronics products made from PET include insulating films, electrical connectors, insulators, circuit boards, wiring insulation, and transistor and semiconductor components, etc.

2.4. Automotives

PET is used in the automotive industry for various applications due to its desirable properties. It is a strong and rigid material, with good resistance to impact and chemicals, which is suitable for applications such as car interior panels, engine cover, connector housing, windshield wiper arm, door panels, and trim.

2.5. Construction and building materials

PET plastic is incorporated into insulation materials, roofing membranes, and composite panels thanks to its thermal insulation properties, durability, and resistance to moisture. Additionally, PET is used in geotextiles, reinforced concrete, acoustic panels, etc.

2.6. Medical and healthcare

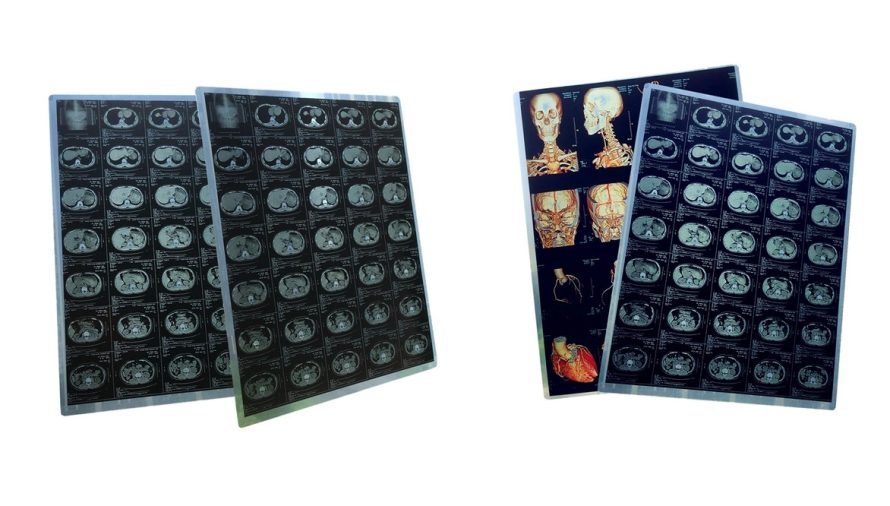

PET is used for medical devices, and diagnostic equipment because of its chemical resistance and barrier properties. Besides, PET films are also used in medical imaging devices, such as X-ray and MRI machines, because PET films are clear and can transmit electromagnetic waves.

Read more: Breaking the Secret: Taical, Filler Masterbatch, and Calpet Explained

3. Conclusion

Polyethylene terephthalate (PET) is. In conclusion, thanks to polyethylene terephthalate’s unique properties, such as transparency, strength, durability, and recyclability, etc, it has become an incredibly versatile material with a wide range of applications across various industries. From everyday items like plastic bottles and clothing to critical components in electronic devices and medical equipment, PET’s adaptability and performance continue to drive its widespread use. As industries seek more sustainable and efficient materials, PET’s role is likely to grow even further, underscoring its importance in modern manufacturing and daily life.

4. About EuP Egypt

EuP Egypt is a member of EuroPlas and the first factory of a Vietnamese enterprise in Egypt. It is easy to see that EuP Egypt is strategically positioned to become a major exporter of high-quality filler masterbatch to the Middle East, Africa, Europe, and the Americas in the near future.

With that direction, EuP Egypt set a first priority to bring customers unique plastic raw material solutions being reliable and efficient to help their factories optimize production costs and improve competitiveness on the market. We are not only the world’s largest filler masterbatch manufacturer, but also provide a diversity of products such as color masterbatch, bioplastics, biofiller, additives, engineering plastic compound, etc.

For further information and consultation, do not hesitate to contact usHow are polyethylene terephthalate products widely used in various industries and in our daily lives? Delve into common items here!!