In today’s material-driven industries, understanding the differences between similar-sounding materials can be crucial for product performance, cost-efficiency, and sustainability. One such common comparison is polyamide vs nylon – terms often used interchangeably, but not quite the same. Whether you’re sourcing materials for textiles, automotive parts, or consumer goods, knowing how these polymers differ in structure, properties, and applications can help you make smarter choices.

1. What Is Polyamide?

Polyamide is a group of polymers linked by amide bonds. In the polyamide vs nylon comparison, polyamide is the broader category, while nylon is just one type. Knowing what polyamide is helps you better understand the key differences in the polyamide vs nylon debate.

Polyamides can be found in both nature and industry.

- Natural polyamides: Examples include silk and wool, which are protein-based fibers produced by living organisms. These have been used for centuries in clothing and luxury textiles.

- Synthetic polyamides: These are engineered materials made through polymerization processes. Nylon and aramids fall into this group. They are designed for strength, durability, and performance in demanding applications.

Key Properties of Polyamides

- High tensile strength: Polyamides are strong and resistant to stretching, making them reliable for load-bearing parts and industrial components.

- Abrasion resistance: Their ability to resist wear from friction makes them ideal for moving parts and high-traffic textile applications.

- Chemical resistance: Polyamides stand up well to oils, solvents, and fuels, which is critical in automotive and mechanical uses.

- Thermal stability: Depending on the type, polyamides can perform reliably at moderate to high temperatures, suitable for electronics and engine components.

- Moisture absorption: They absorb water from the air, which can impact strength and flexibility. This feature is a double-edged sword: useful in textiles, but a factor to consider in precision engineering.

This foundation sets the stage for a clearer look at polyamide vs nylon, where we explore what makes nylon unique within the larger polyamide family.

2. What Is Nylon? A Specific Type of Polyamide

Nylon is a synthetic material that belongs to the broader polyamide family. While polyamide vs nylon are sometimes used interchangeably, nylon refers specifically to certain engineered polyamides known for their strength, durability, and versatility in both textile and industrial applications.

Nylon was first developed in the 1930s by Wallace Carothers and his research team at DuPont. Intended as a man-made alternative to silk, it gained commercial success with its launch in women’s hosiery in 1939. Its usefulness expanded rapidly during World War II, when it replaced scarce natural fibers in military gear like parachutes, tents, and ropes, thanks to its high strength-to-weight ratio and resistance to wear. This marked the beginning of nylon’s evolution from a textile innovation to a high-performance material used in countless applications.

Over time, several variations of nylon have been created to meet different technical requirements:

- Nylon 6, made from caprolactam, is valued for its toughness, elasticity, and smooth surface finish. It’s widely used in textile fibers, films, and light engineering parts.

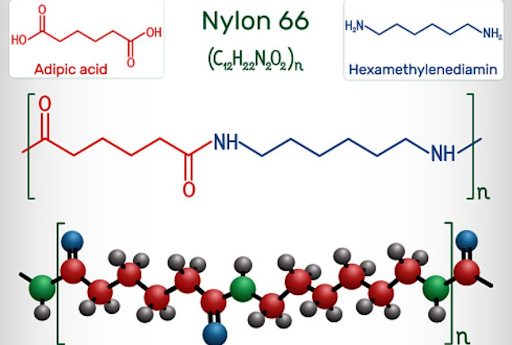

- Nylon 66, produced from a two-monomer system, offers improved heat resistance, rigidity, and durability. It’s ideal for automotive components, electrical housings, and structural applications.

- Other forms, such as Nylon 11 and Nylon 12, are known for their flexibility and low moisture absorption. These are often chosen for tubing, fuel systems, and environments where dimensional stability is crucial.

3. Polyamide vs. Nylon: Key Differences

3.1. Terminology and Classification

All nylons are polyamides, but not all polyamides are nylons. In the context of polyamide vs nylon, “polyamide” is a broad term used to describe polymers made from repeating units linked by amide bonds. This includes both natural fibers like silk and wool, and synthetic versions like nylon and aramids.

Nylon, by contrast, refers to a specific group of synthetic polyamides developed for strength, flexibility, and chemical resistance. It’s one of the most recognized and widely used materials within the polyamide family.

In short, if a material is nylon, it’s always a polyamide. But if a material is labeled as polyamide, it could be nylon, or something else entirely.

3.2. Chemical Structure

The difference in chemical structure comes down to the type of monomers used and how they’re linked. Nylons are usually made using one or two specific monomers in a controlled reaction, which gives them predictable performance and processing behavior.

Other polyamides may use different chemical setups, resulting in variations in stiffness, thermal resistance, or flexibility. This makes them suitable for different types of environments or technical demands.

3.3. Physical Properties

Both materials are strong and durable, but they don’t perform exactly the same. Nylon is known for its balance between strength, toughness, and lightweight. It also offers good flexibility and abrasion resistance, making it popular in both fabrics and molded parts.

When comparing polyamide vs nylon, some other polyamides may be stiffer, more heat-resistant, or better at holding shape, but could also be harder to process or more expensive. The best choice depends on what properties matter most for your application.

3.4. Moisture Absorption

Synthetic polyamides can absorb moisture from the environment, which may affect their shape or performance over time. Nylon, in particular, tends to take in more moisture than some other types.

This isn’t always a problem, it can even help in certain textile or flexible applications, but in situations where dimensional stability is critical, a lower-absorption polyamide may be the better fit.

3.5. Cost and Availability

Nylon is widely produced, easy to source, and available in many forms. Because of its high demand and global supply, it’s often more affordable than some of the more specialized polyamides.

From a polyamide vs nylon perspective, other types may be more costly due to limited availability or higher performance, especially those used in extreme environments or engineered for specific properties.

4. Applications: When to Use Polyamide vs. Nylon

Nylon Applications

Nylon is widely used in industries that require strong, lightweight, and versatile materials. Its ease of processing and reliable performance make it a popular choice for:

- Textiles and Apparel: Nylon is commonly found in clothing, sportswear, swimwear, and backpacks. It’s valued for its stretch, durability, and resistance to abrasion, making it ideal for active use. In the context of polyamide vs nylon, nylon dominates this space due to its comfort and affordability.

- Injection-Molded Parts: In manufacturing, nylon is used for mechanical components like gears, bushings, and fasteners. It offers a good balance of strength and flexibility for parts that need to handle daily stress.

- Consumer Goods: Everyday products like toothbrushes, zippers, fishing lines, and packaging films often use nylon because it’s tough, affordable, and easy to shape into fine, detailed forms.

Other Polyamide Applications

In the discussion of polyamide vs nylon, other synthetic polyamides are chosen when standard nylon isn’t enough, especially in high-performance or extreme environments.

- Engineering and Industrial Uses: Some polyamides are more rigid or heat-resistant than nylon, making them better suited for engine parts, friction components, and structural pieces in machinery or electronics.

- Chemical-Resistant Parts: For seals, tubing, and containers exposed to oils, fuels, or aggressive solvents, certain polyamides offer better chemical stability and dimensional control.

- Protective Equipment and Specialty Fabrics: Advanced polyamides like aramids are used in ballistic fabrics, fire-resistant gear, and industrial belts where extra strength and safety are required.

Natural Polyamide Applications

Natural polyamides like wool and silk are valued for their comfort, biodegradability, and performance in apparel and lifestyle products. Though not used in industrial settings like their synthetic counterparts, they remain essential in textiles and fashion.

- Wool Textiles and Apparel: Wool is used in garments such as sweaters, suits, and outerwear thanks to its natural insulation, breathability, and moisture-wicking ability. It’s also common in blankets and performance clothing for colder climates.

- Silk in Fashion and Bedding: Silk is prized for its softness, sheen, and lightweight. It’s often used in high-end clothing, scarves, ties, and luxury bedding due to its smooth texture and natural temperature regulation.

- Eco-Friendly and Biodegradable Materials: Wool and silk are popular in sustainable fashion and product design. Unlike synthetics, they naturally break down over time and require fewer chemicals to produce, appealing to brands and consumers focused on environmental impact.

5. Polyamide vs. Nylon: Which Should You Choose?

The decision between polyamide vs nylon comes down to what your product needs to handle in terms of performance, environment, and budget.

Nylon is the better option when you’re looking for a reliable, all-purpose material that performs well in standard conditions. It’s widely used in clothing, consumer goods, and lightweight parts because it offers a good mix of strength, flexibility, and affordability. Thanks to its ease of processing and broad availability, nylon is often the default choice for high-volume production.

On the other hand, if your application involves higher temperatures, exposure to harsh chemicals, or requires more structural stability, other synthetic polyamides may be a better fit. These materials can deliver higher performance where nylon may fall short, especially in engineering, automotive, or heavy-duty industrial environments. While they tend to be more expensive and may require more careful handling, their advanced properties make them the right solution for demanding use cases.

In short, when considering polyamide vs nylon, nylon is a practical, cost-effective material for everyday needs, while other polyamides are worth considering when your project pushes beyond standard performance limits.

6. Environmental Impact and Sustainability

As demand for durable and high-performance materials grows, so does the need to consider their environmental impact. Both polyamide vs nylon raise concerns related to production, disposal, and long-term sustainability.

Production Concerns

Synthetic polyamides, including nylon, are derived from petrochemicals through energy-intensive processes. The manufacturing of these materials typically involves high heat and pressure, leading to significant carbon emissions. In some cases, toxic byproducts or greenhouse gases like nitrous oxide may also be released. Additionally, fossil-based feedstocks make these materials non-renewable, contributing to resource depletion.

Recycling Potential

Polyamides can technically be recycled, but the process is not always straightforward. Mechanical recycling often results in downgraded quality, while chemical recycling requires complex infrastructure and is still not widespread. Nylon, in particular, has seen more progress in this area with initiatives for closed-loop recycling in textiles and carpets. However, large-scale systems for polyamide recovery remain limited, and much of the material still ends up in landfills or incinerators.

Eco-Friendly Alternatives

To reduce environmental impact, companies and manufacturers are exploring more sustainable options. Natural polyamides, such as wool and silk, offer built-in advantages: they are biodegradable, renewable, and require less processing energy compared to synthetics. These materials naturally decompose without releasing harmful residues, making them ideal for eco-conscious product lines.

Another promising direction is bio-based synthetic polyamides, which are made from renewable feedstocks instead of fossil fuels. For example, EuP Egypt offers bioplastic solutions that include bio-based polyamide alternatives, helping manufacturers reduce their carbon footprint without compromising on performance. These next-generation materials are designed to deliver strength and durability while aligning with circular economy goals.

As sustainability becomes a bigger priority, the choice of polyamide type, and how it’s sourced and processed, can have a major impact on both product and planet.

7. FAQs About Polyamide and Nylon

Are polyamide and nylon the same thing?

Polyamide vs nylon are not exactly the same thing. Nylon is a type of synthetic polyamide, but not all polyamides are nylon. Polyamide is the broader category that includes nylon, aramids, and even natural fibers like wool and silk.

Is polyamide fabric breathable?

Yes, polyamide fabrics can be breathable, especially in lightweight weaves. However, breathability depends more on fabric construction than the fiber itself.

Which is better for outdoor gear: nylon or polyamide?

Nylon is often preferred for outdoor gear due to its durability and water resistance. But certain polyamides offer better heat or chemical resistance, depending on the application.

How do I identify nylon vs. other polyamides?

It can be tricky without lab testing. Labels and product specs often identify nylon by its type (e.g., Nylon 6 or 6,6), while other polyamides may be listed under technical codes or brand names.

Are nylon and polyamide UV-resistant?

Both polyamide vs nylon can degrade under UV exposure over time. However, UV resistance can be improved with additives or coatings during manufacturing.

8. Conclusion

Choosing between polyamide vs nylon ultimately depends on your product’s requirements. Nylon remains a reliable, cost-effective choice for general applications, while other polyamides may offer higher performance in demanding environments. As industries continue to push for better materials and more sustainable production, advanced polymer solutions play a critical role.

If you’re looking for high-quality plastic compounds tailored to modern manufacturing needs, EuP Egypt is here to support your success. As a global leader in polymer solutions, EuP Egypt supplies a wide range of plastic compounds, including PA6 compound and PA66 compound, trusted by manufacturers worldwide for their strength, consistency, and processing reliability.

With over 17 years of industry expertise, modern production facilities, and a presence in more than 90 countries, EuP Egypt is more than just a supplier – we’re a technical partner focused on helping you improve efficiency, reduce material waste, and meet evolving market demands. Looking for a custom compound solution? Contact EuP Egypt today if you want to take your production to the next level!