Calcium carbonate filler masterbatch helps Turkish plastic manufacturers cut costs while maintaining quality. Importing from nearby regions like Egypt offers affordable, high-quality options with fast delivery, making it a smart choice for films, packaging, and more.

1. Why Calcium Carbonate Filler Masterbatch Matters in Turkey’s Plastics Industry

Turkey’s plastics industry thrives on producing packaging, pipes, and household goods for global markets. But rising raw material costs challenge manufacturers to stay competitive without compromising quality.

What’s the best way to source affordable, reliable filler masterbatch?

Calcium carbonate (CaCO3) filler masterbatch is a smart solution, reducing reliance on expensive virgin resin while preserving strength and processability. With local suppliers often charging premium prices, imports from regions like Egypt or Vietnam provide cost-effective, high-quality alternatives, helping Turkish producers boost profitability.

2. Understanding Calcium Carbonate Filler Masterbatch

What Is CaCO3 Filler Masterbatch?

Calcium carbonate filler masterbatch is a blend of finely ground calcium carbonate (CaCO3), polymer resin, and additives like dispersing agents. Used as a cost-effective additive, it partially replaces virgin resin in plastic production, reducing costs while preserving durability and processability.

Key Benefits for Turkish Manufacturers

-

Cost Savings: Replacing 10-30% of virgin resin with CaCO3 filler can lower material costs significantly, especially for high-volume products like films or bags.

-

Enhanced Properties: Well-formulated fillers improve stiffness, printability, and surface finish, ideal for packaging and molding.

-

Smoother Processing: Good dispersion reduces machinery wear, speeds up extrusion, and cuts cycle times.

-

Eco-Friendly Edge: Using less virgin resin reduces environmental impact, aligning with sustainable manufacturing trends.

Common Applications in Turkey

CaCO3 filler is versatile, supporting Turkey’s diverse plastics sector:

-

Blown Film and Packaging: Used in shopping bags, trash liners, and agricultural films for cost-effective strength.

-

Injection Molding: Ideal for household goods, caps, and containers needing durability.

-

Pipes and Sheets: Balances cost and toughness for construction and industrial uses.

-

Woven Sacks and Raffia: Enhances strength in agriculture and packaging bags.

3. Plastic Manufacturing Landscape in Turkey

Turkey is one of the largest plastics producers in the region, with an annual production capacity of over 10 million tons. In 2024, the industry is expected to generate around 53 billion USD in revenue (Plast Eurasia, plasteurasia.com).

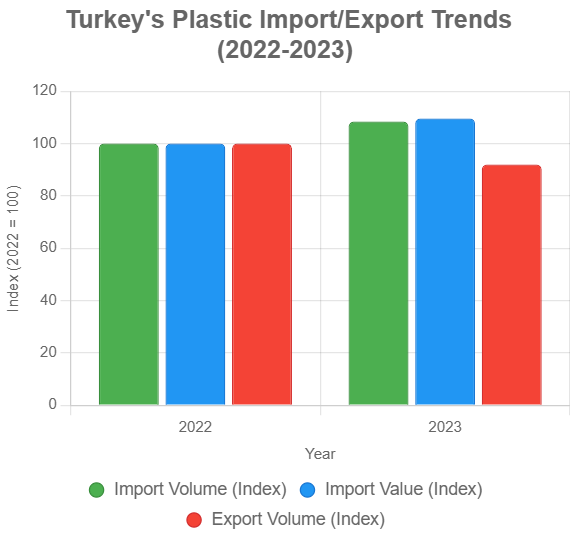

Demand at home remains strong: in the first nine months of 2023, local output of finished plastic goods grew by 3.9% in volume and 6.3% in value compared to the previous year. However, imports rose even faster—8.4% in volume and 9.6% in value—while exports fell by nearly 8% in the same period (PAGEV, pagev.org).

The biggest challenge for Turkish manufacturers is their reliance on imported raw materials, which account for about 85% of the sector’s needs (PLASFED, plasfed.org.tr).

With petrochemical prices and freight costs rising, local producers face shrinking margins. This creates strong demand for cost-effective raw material solutions—such as calcium carbonate filler masterbatch—that can help Turkish converters stay competitive without sacrificing quality.

4. Price and Quality – The Critical Factor for Turkey’s Buyers

In Turkey’s plastic industry, cost and quality go hand in hand. Most manufacturers here already know that local filler masterbatch suppliers are expensive. Paying too much for raw materials eats into margins, but lowering quality isn’t an option either—customers expect strong, reliable products.

That’s why buyers are now looking for a smarter middle ground: good quality at a better price. With raw materials mostly imported and prices constantly shifting, converters are under pressure to cut costs wherever possible.

Imported calcium carbonate filler masterbatch has become a practical solution. Suppliers close to Turkey, like those in Egypt, can deliver consistent quality backed by global standards while keeping prices competitive. For many producers, this balance—affordable yet dependable—is exactly what they need to stay profitable and keep their products competitive in both local and export markets.

5. Advantages of Importing Calcium Carbonate Filler Masterbatch

Cost Savings from Imports

Is imported filler masterbatch cheaper than local in Turkey?

Yes, imported calcium carbonate (CaCO3) filler masterbatch often costs less than local options.

Regions like Egypt benefit from abundant limestone and large-scale production, offering prices 10-20% lower than Turkish suppliers. For high-volume products like films or woven sacks, these savings boost profitability without compromising quality.

| Aspect | Local Fillers (Turkey) | Imported Fillers (e.g., Egypt) |

| Price | Higher (~$500-700/ton) due to limited raw materials and production scale | Lower (~$300-400/ton), 15-30% savings from economies of scale and proximity |

| Quality | Consistent but variable; often meets basic standards | High and reliable; backed by ISO/REACH certifications for global performance |

| Lead Time | Short (1-3 days domestically) | Efficient (3-5 days via Mediterranean/nearby routes), with low inventory risks |

Logistics Advantages

Turkey’s location makes importing efficient. Nearby suppliers, like those in Egypt, ensure short shipping times across the Mediterranean, often under a week. This reduces inventory risks compared to longer routes from Asia (e.g., India or Vietnam). Reliable logistics help manufacturers maintain steady production and avoid costly delays.

Quality and Customization

Imported fillers can match or exceed local quality. Reputable suppliers follow global standards like ISO and REACH, ensuring consistent performance in extrusion or molding.

Many also offer tailored formulations, such as fillers for high-printability films or durable pipes, meeting Turkey’s diverse manufacturing needs.

6. How Turkish Plastic Manufacturers Can Maximize Benefits

Choosing the Right Filler Masterbatch Supplier

How can I maximize savings with CaCO3 filler masterbatch? Start by selecting a supplier with proven credentials. Look for ISO or REACH certifications to ensure consistent quality.

Suppliers offering technical support can help optimize filler use for your specific needs, reducing trial-and-error costs in production.

How to Calculate Cost Savings

How much can I save with CaCO3 filler masterbatch?

Use this formula: Savings = (Virgin Resin Price – Filler Price) × Replacement Percentage

For example, if resin costs $1,200/ton, filler costs $400/ton, and you replace 20%, savings are ($1,200 – $400) × 0.2 = $160/ton. Focus on high-volume products like films to maximize impact. Nornally, savings can reach 10-30% on raw material costs, especially in high-volume applications like films, woven sacks, or pipes.

Optimizing Filler Use

Test fillers in small runs to find the ideal replacement rate. Adjust formulations to maintain strength and printability, ensuring quality for applications like sacks or pipes.

Long-Term Strategies

Build long-term supplier relationships for consistent stock and tailored solutions. Regular testing and feedback allow you to refine filler use, minimizing waste.

Focus on high-output products to maximize savings, keeping your operations competitive in Turkey’s plastics market.

7. Why EuP Egypt Is a Trusted Partner for Turkey’s Plastic Industry

For Turkish converters searching for a balance between price and quality, EuP Egypt offers a solution that goes beyond cost savings. As part of EuP Group with more than 17 years of experience and exports to over 95 countries, we bring global expertise and proven reliability to every shipment.

Our strength begins at the source. EuP Egypt’s filler masterbatch is produced from high-purity limestone quarried in Egypt, processed with German-engineered technology, and blended with premium resins and additives from trusted suppliers like Sabic and BASF. Every batch is manufactured under strict quality systems and international certifications including ISO and REACH, giving Turkish buyers confidence in consistent performance and compliance with global standards.

EuP Egypt also offers a full portfolio of filler solutions:

- PE filler masterbatch for films, bags, and containers

- PP filler masterbatch for woven sacks, sheets, and rigid plastics

- HIPS filler masterbatch for impact-resistant polystyrene products

- Transparent filler masterbatch for cost savings without sacrificing clarity

Price competitiveness is where we stand out. With a production capacity of 200,000 tons per year and economies of scale, we can supply filler masterbatch at rates far more attractive than most local suppliers in Turkey. Combined with our strategic location just across the Mediterranean, Turkish manufacturers benefit from shorter delivery times, lower logistics costs, and more reliable supply.

Finally, EuP Egypt sees partnerships as long-term commitments. Our R&D and technical support teams work directly with customers to tailor formulations for specific needs, ensuring that every converter—from film extrusion to injection molding—can maximize performance while lowering production costs.

This combination of affordable pricing, trusted quality, and fast logistics makes EuP Egypt a partner that Turkish manufacturers can rely on as they navigate today’s competitive plastic market.

8. Conclusion

Calcium carbonate (CaCO3) filler masterbatch helps Turkish plastic manufacturers cut costs by 10-30% while maintaining quality for films, pipes, and packaging. Importing from regions like Egypt or India offers affordable, reliable options with fast delivery, keeping producers competitive. By choosing certified suppliers and optimizing filler use, manufacturers can boost profitability without sacrificing performance.

Ready to lower your production costs?

Explore imported CaCO3 fillers or request a sample quote to see savings in action, ensuring your business thrives in Turkey’s dynamic plastics market.

9. FAQs about Calcium Carbonate Filler Masterbatch in Turkey

What is CaCO3 filler masterbatch used for in Turkey?

It’s used in films, bags, pipes, and containers, reducing resin costs while maintaining strength and printability for packaging, construction, and agriculture.

Is imported filler masterbatch cheaper than local in Turkey?

Yes, imports from Egypt or India are often 10-20% cheaper than local suppliers, offering similar quality with cost savings for high-volume plastics.

Does EuP Egypt’s filler masterbatch meet international standards?

Absolutely. EuP Egypt produces filler masterbatch with high-purity limestone and advanced German technology. All products are certified under ISO and REACH, ensuring consistent quality and compliance with global regulations.

How fast can Turkish manufacturers receive filler masterbatch from EuP Egypt?

Thanks to our location just across the Mediterranean, deliveries are faster and shipping costs are lower compared to distant suppliers. This helps Turkish manufacturers keep a steady supply and reduce inventory risks.