Are you struggling to choose between fiberglass and carbon fiber for your next project? With so many differences in strength, weight, cost, and performance, making the right decision can feel overwhelming—especially when precision matters. This article breaks down everything you need to know about GFRP (glass fiber reinforced plastic) and CFRP (carbon fiber reinforced plastic) to help you compare their pros, cons, and ideal applications—so you can pick the right material with confidence.

TL;DR: Quick Guide to Choosing GFRP vs CFRP

- Fiberglass (GFRP): Cheaper, flexible, impact-resistant, ideal for boats, construction, and budget projects.

- Carbon Fiber (CFRP): Stronger, lighter, pricier, best for aerospace, sports, and high-performance vehicles.

- Eco-Friendly? GFRP uses less energy to produce but is harder to recycle; CFRP recycling is improving but costly.

- Not Sure? Test a prototype or consult a materials engineer for tailored advice.

1. Head-to-Head Comparison: Fiberglass vs Carbon Fiber

When it comes to performance materials, fiberglass and carbon fiber are both popular—but they serve very different needs. Let’s break them down side-by-side, so you can clearly see where each one shines and where it might fall short.

1.1. Material Composition & Manufacturing

Fiberglass, or GFRP (glass fiber reinforced plastic), is made by weaving glass fibers (e.g., E-glass or S-glass) into mats, bonded with resins like polyester or epoxy. E-glass is cost-effective, while S-glass offers enhanced strength for demanding applications. Manufacturing via hand layup or resin transfer molding (RTM) is scalable, per ASTM D6507.

Carbon fiber, or CFRP (carbon fiber reinforced plastic), uses high-strength carbon filaments (e.g., PAN-based) set in epoxy resin for superior stiffness. Its production, like autoclave curing, demands precision and specialized equipment, increasing costs.

1.2. Mechanical Properties

If you’re looking for raw strength and stiffness, carbon fiber takes the win. It has a much higher tensile strength and stiffness (aka “Young’s modulus”) than fiberglass. That means it resists stretching or bending better under stress.

But here’s the catch: carbon fiber is more brittle. It can crack or fail suddenly under extreme impact, while fiberglass tends to bend or absorb shock.

1.3. Flexibility & Damage Tolerance

Fiberglass is more forgiving when things go wrong. It absorbs impact without cracking right away. That’s why it’s a go-to for boat hulls, car panels, and construction materials.

Carbon fiber is stiff and light, but it doesn’t flex much. Under a sudden hit or drop, it can fracture instead of bending.

1.4 Thermal & Electrical Behavior

This is where things get technical—but we’ll keep it simple.

Fiberglass doesn’t conduct electricity. It’s a great insulator and can handle high temperatures without deforming. It’s often used in electrical and industrial settings for that reason.

Carbon fiber, on the other hand, does conduct electricity. That’s great for some aerospace or automotive applications, but risky around electronics or in corrosive environments unless properly insulated.

Quick Recap:

| Property | Fiberglass (GFRP) | Carbon Fiber (CFRP) |

| Composition | Glass + resin | Carbon + resin |

| Strength | Good | Excellent |

| Flexibility | High | Low |

| Weight | Moderate | Very light |

| Conductivity | Non-conductive | Conductive |

| Cost | Low | High |

| Ease of Repair | Easy | Difficult |

2. Application-wise Suitability: Where Each Material Works Best

Now that you know how fiberglass and carbon fiber compare in terms of performance, let’s look at where each material really shines in the real world. Choosing the right one depends on what you need—budget, strength, flexibility, or durability.

2.1 Best for Budget and Everyday Use: Fiberglass

If you’re working with a tight budget or mass production, fiberglass (GFRP plastic) is the go-to material. It’s widely used in:

- Construction (like wall panels, roofing, rebar). GFRP rebar in bridges reduced costs by 20% compared to steel while resisting corrosion (per ASTM C581).

- Marine products (boats, kayaks)

- Automotive parts (body panels, spoilers)

- Consumer goods (tubs, helmets, storage tanks)

Why? It’s cheaper, easier to shape, and more forgiving when it comes to impact and wear. You can mold it into complex shapes without expensive equipment, and repairs are simple and affordable.

Is fiberglass good for car parts?

Yes, fiberglass is great for car parts that need flexibility and moderate strength, like bumpers or body kits.

2.2 Best for Performance and Precision: Carbon Fiber

If performance is your top priority, carbon fiber is worth the investment. It’s the material of choice in:

- Aerospace and aviation (aircraft frames, satellite components): Boeing’s 787 Dreamliner uses 50% CFRP, cutting weight by 20% and improving fuel efficiency by 15%

- High-end automotive (supercars, F1 bodywork)

- Sports equipment (racing bikes, tennis rackets)

- Medical devices (prosthetics, braces)

What sets CFRP apart is its high strength-to-weight ratio and rigidity. In industries where every gram counts, CFRP delivers unmatched performance.

2.3 When Impact Resistance Matters: Fiberglass

In environments where materials take repeated hits—like off-road vehicles, marine hulls, or heavy-duty storage tanks—fiberglass holds up better under stress. Its flexibility helps absorb force instead of cracking.

Tip: If you’re designing something that might get dropped, bumped, or hit, fiberglass is often the smarter, safer choice.

2.4 For Harsh or Outdoor Conditions

Both materials resist corrosion, but GFRP handles UV and chemicals better in many cases. It’s often used in outdoor electrical boxes, bridges, and cooling towers.

CFRP is better at handling extreme temperatures without warping—but be cautious of its conductivity in electrical or marine settings.

3. Hybrid & Advanced Solutions: Getting the Best of Both Worlds

Sometimes, you don’t have to pick just one. Engineers and manufacturers are increasingly turning to hybrid composite materials to combine the strengths of both fiberglass and carbon fiber.

3.1 Blended Composites for Balanced Performance

Some manufacturers are now layering different fibers—for example, combining carbon and glass fibers within a single laminate. These hybrid composites aim to balance the best features of both materials:

- Carbon fiber brings high stiffness and low weight.

- Fiberglass adds flexibility and improves impact resistance.

- The overall cost is lower than pure CFRP.

This blend is especially useful in applications like automotive panels, sports equipment, and industrial machinery—where a single material might fall short. For example, a racing bike frame might use carbon fiber for its stiffness, but add fiberglass to improve durability and rider comfort.

Can you combine carbon fiber and fiberglass?

Yes. Hybrid composites are widely used to create a balance of strength, flexibility, and cost-effectiveness.

3.2 New Frontiers: Resin Innovation and Recyclable Composites

It’s not just the fibers that are evolving—resins and manufacturing methods are getting smarter too.

- Prepreg composites come pre-impregnated with resin, allowing for higher precision and performance.

- Recycled carbon fiber is now being used in cost-sensitive applications like laptop casings or interior auto parts.

- Bio-based resins and thermoplastics are helping make composites more sustainable and easier to recycle.

These advancements open the door for more responsible, tailored, and efficient use of both GFRP and CFRP in the future.

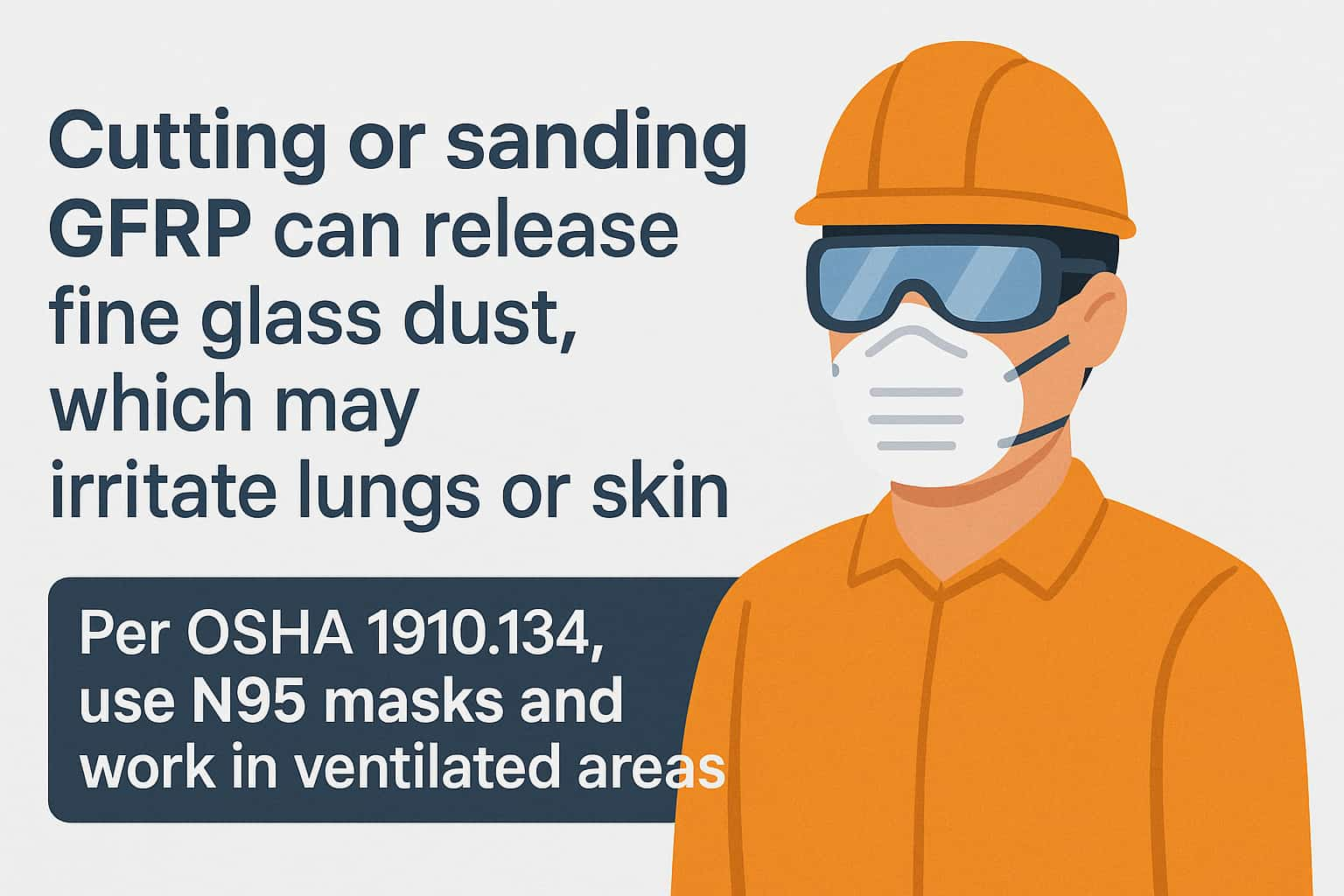

3.3 Health and Safety Considerations

Handling GFRP and CFRP requires precautions to ensure safety:

- Fiberglass (GFRP): Cutting or sanding GFRP can release fine glass dust, which may irritate lungs or skin. Per OSHA 1910.134, use N95 masks and work in ventilated areas. Dispose of GFRP waste at certified recycling facilities to avoid landfill hazards.

- Carbon Fiber (CFRP): CFRP splinters can cause skin irritation or embed in tissue; wear gloves during handling. Dust from machining CFRP requires HEPA-filtered vacuums to prevent inhalation .

Disposal: GFRP is harder to recycle but has lower production emissions (~2 kg CO2/kg vs. CFRP’s ~20 kg CO2/kg). Emerging CFRP recycling methods, like pyrolysis, recover up to 70% of fibers.

Pro Tip: Always follow manufacturer safety data sheets (SDS) for resins and use PPE during processing.

4. Design & Engineering Considerations: What You Need to Know Before Choosing

Choosing between fiberglass and carbon fiber isn’t just about strength or cost. If you’re designing a product or structure, you need to understand how each material behaves in use. That means thinking beyond raw properties and considering how the material performs under stress, how it’s shaped, and how long it will last.

Fiber Orientation Matters

One of the first things engineers consider with both GFRP and CFRP is fiber orientation. Unlike metals, these materials are anisotropic—which means they don’t behave the same in every direction.

If the fibers are aligned in one direction, the material will be strongest in that direction but weaker in others. This is why layup design (the way fibers are arranged in layers) is so critical. Poor layup can lead to failure even if the material itself is strong.

For simple shapes or non-structural parts, fiberglass is easier to handle because it’s more forgiving. Carbon fiber requires more precise engineering to get the most out of its strength.

Fatigue and Lifespan

Carbon fiber is incredibly stiff, but that comes at a cost. It can be brittle and may not handle long-term fatigue or repeated stress as well as fiberglass. Over time, small cracks or delamination (layers separating) can weaken CFRP components.

Fiberglass is better at absorbing shock and tends to last longer in environments where parts are constantly moving or being hit. It’s also easier and cheaper to repair if something goes wrong.

Weight vs Durability

If weight is a top priority—say, for drones, performance vehicles, or aircraft—carbon fiber is often the only real choice. But if you’re working on infrastructure, large equipment, or parts exposed to the elements, fiberglass may offer a better balance between strength, flexibility, and resistance to environmental wear.

In short, the right material choice depends not just on what the product needs to do—but how it will be made, used, and maintained over time.

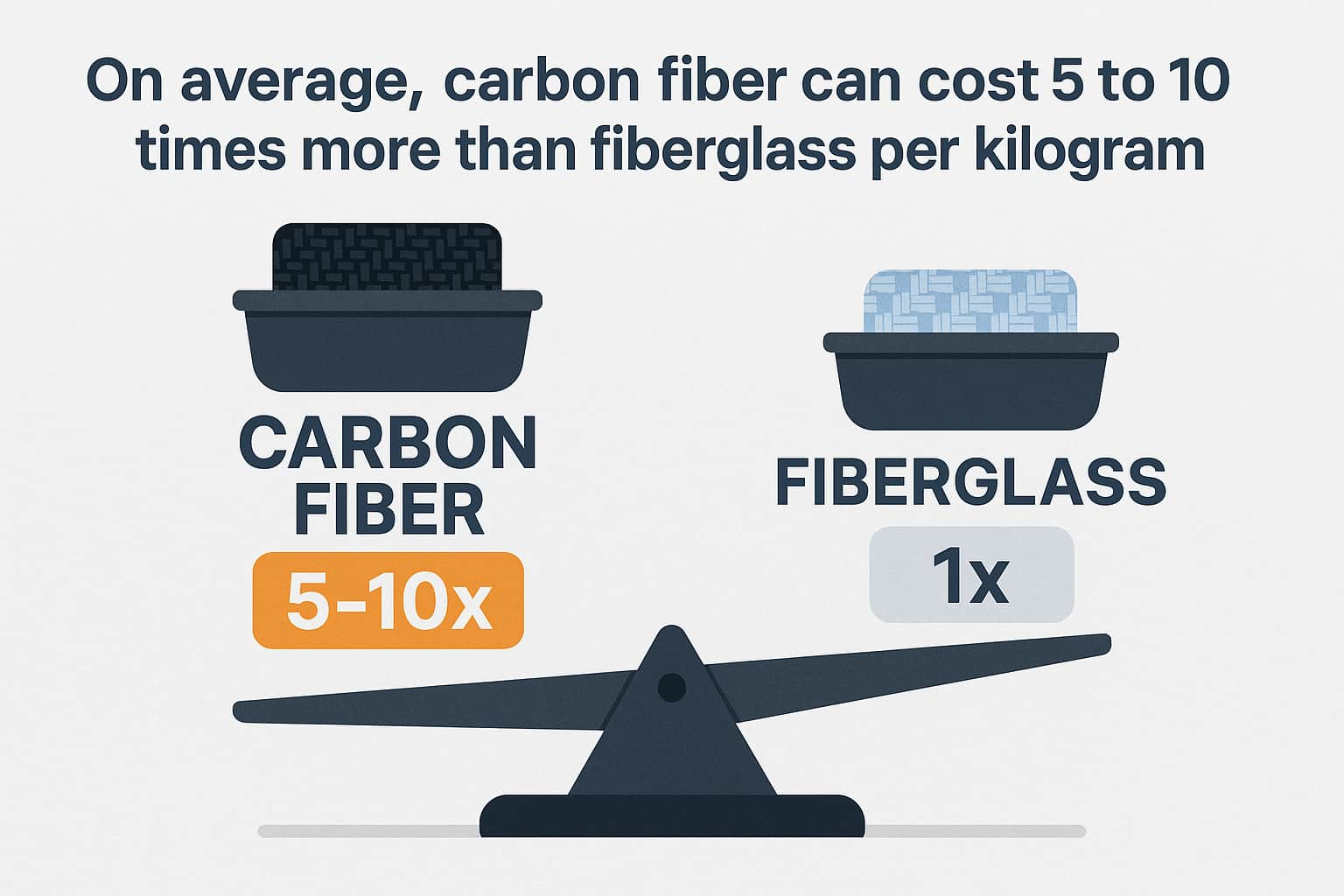

5. Cost Comparison: Breaking Down the Numbers

When choosing between fiberglass and carbon fiber, cost is often the deciding factor—especially for large projects or commercial production. While carbon fiber offers higher performance, it comes at a much steeper price. Fiberglass, on the other hand, is far more budget-friendly and accessible.

Let’s break down the typical costs and related expenses so you can see the full picture.

How Much More Expensive Is Carbon Fiber?

On average, carbon fiber can cost 5 to 10 times more than fiberglass per kilogram. And that’s just for the raw material. When you add in processing costs, tools, and labor, the price gap becomes even wider.

Carbon fiber also requires more precise handling and equipment, which can raise production costs significantly—especially if you’re using prepreg sheets or autoclaves for curing.

Fiberglass, meanwhile, is much easier to mold, cure, and repair. It’s widely used in industries where cost and durability matter more than ultra-lightweight performance.

Repair and Maintenance Costs

Repairing fiberglass is cheaper and simpler. Small cracks or surface damage can often be fixed with basic materials and tools. With carbon fiber, repairs usually require specialized skills and equipment—and the results may not fully restore original strength.

Cost Comparison Table

| Feature | Fiberglass (GFRP) | Carbon Fiber (CFRP) |

| Material Cost (per kg) | ~$2–$5 | ~$20–$50 |

| Manufacturing Cost | Low to moderate | High |

| Tooling Requirements | Basic molds | Specialized equipment |

| Repair Cost | Low | High |

| Production Scale | Ideal for mass production | Best for high-end, low-volume parts |

Tip: If your project doesn’t demand ultra-lightweight materials or extreme stiffness, fiberglass will almost always offer better value for money.

6. Decision Framework: When to Choose What

After comparing fiberglass and carbon fiber from every angle—strength, flexibility, cost, and applications—you might still be wondering: Which one is right for me? The answer depends on your specific goals, budget, and how the material will be used.

This simple framework will help you make a confident, informed decision.

What’s the Best Material for Budget Projects? (GFRP)

- You’re on a tight budget: GFRP costs $2–$5/kg vs. CFRP’s $20–$50/kg.

- You need impact resistance: GFRP absorbs ~80 J of impact energy, ideal for boats or car panels [1].

- You’re making large parts: GFRP’s moldability suits construction panels or storage tanks.

- You want easy repairs: GFRP patches are simple and cost ~$10–$20.

- You’re facing harsh conditions: GFRP resists UV and chemicals better (per ASTM G154).

- You’re scaling production: GFRP’s low cost suits mass production.

Examples: Boat hulls, electrical enclosures, Toyota Corolla spoilers.

What’s the Best Material for High-Performance Projects? (CFRP)

- You need maximum strength: CFRP’s superior strength suits high-performance needs

- Lightweight is critical: CFRP’s density (1.6 g/cm³) is lower than GFRP’s (1.8–2.0 g/cm³).

- You’re in aerospace or sports: CFRP shines in aircraft wings or racing bikes.

- You have specialized tools: CFRP requires autoclaves or prepreg systems.

- You need precision: CFRP maintains stability at 200°C, per SAE J2260.

- You can afford premium costs: Budget for $20–$50/kg and higher labor costs.

Examples: Boeing 787 components, McLaren P1 chassis, Wilson tennis rackets.

Can you replace carbon fiber with fiberglass?

It depends on the application. For non-critical parts or where cost matters more than strength, fiberglass can be a good substitute. But for performance-driven uses, carbon fiber still leads.

If you’re still unsure, consider starting with a small prototype or sample run. That way, you can test the performance and cost-effectiveness of each material before committing to large-scale production.

7. Conclusion & Next Steps

Choosing between fiberglass (GFRP) and carbon fiber (CFRP) depends on your project’s needs—budget, strength, or durability. GFRP offers cost-effective flexibility for construction, marine, and automotive applications. CFRP delivers unmatched stiffness and lightweight performance for aerospace, sports, and high-end automotive uses, despite higher costs.

But what if you’re looking for a solution that goes beyond the basic materials? That’s where engineering compounds come in.

EuP Egypt, a member of EuP Group – a leader in the masterbatch industry since 2008, provides high-performance materials for industries like automotive and construction. Certified to ISO 9001 and ISO 14001, we’ve supplied glass fiber-reinforced engineering compounds for over 500 projects, including electrical enclosures and bridge panels.

Our portfolio includes:

- PC glass fiber compound for high-impact, high-strength applications

- PP glass fiber compound offering excellent stiffness, dimensional stability, and affordability

- ABS glass fiber compound that enhance toughness and resist heat deformation

- PA6, PA66 glass fiber compounds for structural parts requiring superior mechanical strength and long-term durability

While we specialize in GFRP, this article provides an objective comparison of GFRP and CFRP based on industry standards. Contact us at info@eupegypt.com or visit Contact us for inquiries.

People Also Ask: Common Questions Answered

Q: Is fiberglass stronger than carbon fiber?

A: No, carbon fiber (CFRP) is stronger, with tensile strengths of 2000–3500 MPa compared to fiberglass (GFRP) at 500–1000 MPa. However, GFRP is more flexible and better at absorbing impacts without cracking, making it suitable for rugged applications like boat hulls.

Q: How long does carbon fiber last?

A: CFRP can last 10–20 years in controlled environments (e.g., aerospace parts), but UV exposure or cyclic stress may cause delamination over time. Proper epoxy coatings and maintenance extend lifespan, per ASTM G154 testing.

Q: Is fiberglass environmentally friendly?

A: GFRP has a lower production footprint than CFRP and is improving in recyclability, but challenges remain. See Section 3.3 for detailed sustainability comparisons.

Q: Can carbon fiber be recycled?

A: Yes, CFRP can be recycled, with methods recovering up to 90% of fibers for non-structural uses.

References:

- CompositesWorld, “Glass Fiber Types and Properties,” 2024.

- SAE International, “Carbon Fiber Manufacturing Standards,” 2023.

- ASTM D3039, “Tensile Properties of Composites,” 2023.

- ASTM G154, “UV Exposure Testing,” 2023.

- OSHA 1910.134, “Respiratory Protection,” 2023.

- CompositesWorld, “Safe Handling of Carbon Fiber,” 2024.

- Journal of Cleaner Production, “CFRP Recycling Advances,” 2025.