Struggling to find materials that are both strong and sustainable? Glass Fiber Reinforced Plastic (GFRP palstic) delivers high-performance durability without the environmental burden of traditional materials. Used in everything from construction to wind energy, this fiberglass composite is reshaping how industries build smarter and greener.

TL;DR: Glass Fiber Reinforced Plastic (GFRP) is a lightweight, durable, and eco-friendly composite material ideal for construction, automotive, and renewable energy projects. It offers high strength, corrosion resistance, and design flexibility compared to steel or carbon fiber. While recycling and upfront costs are challenges, innovations and long-term savings make GFRP a smart choice for sustainable building.

1. What is Glass Fiber Reinforced Plastic?

Glass Fiber Reinforced Plastic (GFRP) is a fiber-reinforced composite combining fine glass fibers with a plastic polymer matrix. The result is a lightweight, strong material essential in industries like construction, automotive, and renewable energy.

At the core of GFRP are glass fibers, which provide the material’s strength. These fibers are extremely thin strands of glass, usually made in two main types: E-glass and S-glass.

- E-glass, or electrical-grade glass, is the most commonly used type. It offers good strength, corrosion resistance, and is relatively low-cost—perfect for general-purpose applications.

- S-glass, on the other hand, is known for its superior tensile strength and heat resistance. It’s often used where higher performance is required, such as in aerospace or high-stress components.

But glass fibers alone don’t make the material work. They need a polymer matrix to hold them together and shape the final product. Common matrix materials include polyester, vinyl ester, and epoxy resins. These polymers bind the fibers, distribute stress across them, and give the composite its form and flexibility.

The matrix also plays a big role in protecting the glass fibers from moisture, chemicals, and environmental wear. This combination of a tough matrix and high-strength fibers results in a composite that’s not only strong but also lightweight, corrosion-resistant, and long-lasting.

Technical Specifications of E-Glass and S-Glass

The performance of GFRP plastic depends on the fiber type. Below are key mechanical and thermal properties for E-glass and S-glass:

| Property | E-Glass | S-Glass |

| Tensile Strength (MPa) | 2,400–3,450 | 4,300–4,890 |

| Modulus of Elasticity (GPa) | 70–76 | 85–90 |

| Thermal Conductivity (W/m·K) | 0.8–1.0 | 0.9–1.1 |

| Density (g/cm³) | 2.54–2.60 | 2.46–2.49 |

| Strain at Break (%) | 4.5–5.5 | 5.0–5.7 |

Data sourced from industry standards and material testing reports.

2. Key Properties of GFRP: Why GFRP Outperforms Traditional Materials?

What makes Glass Fiber Reinforced Plastic (GFRP) stand out from traditional materials like steel or aluminum? It all comes down to performance. GFRP plastic offers a unique set of properties:

- High Strength-to-Weight Ratio

GFRP is incredibly strong for how light it is. In fact, it can be up to eight times stronger than steel—but without the added weight. That means structures can be built lighter, which lowers transport and installation costs. It’s a big reason why GFRP is used in everything from wind turbine blades to bridge decks. - Corrosion Resistance

Unlike metal, GFRP doesn’t rust or corrode. It holds up in tough environments—saltwater, chemicals, humidity—with very little maintenance. That makes it perfect for marine, chemical, and coastal applications where durability matters most. - Thermal and Electrical Insulation

GFRP doesn’t conduct heat or electricity, which opens up even more applications. From electrical enclosures to thermal barriers, it provides built-in insulation where metals would need extra materials or coatings. - Design Flexibility

Because GFRP is formed in molds, it can be shaped into almost any form. Curves, angles, complex patterns—no problem. This design freedom helps reduce waste, lower production costs, and speed up manufacturing. - Long-Term Durability

GFRP is tough. It handles stress, impact, and environmental exposure without cracking or breaking down. Its composite durability means products last longer and require fewer repairs over time.

Together, these benefits make GFRP one of the top lightweight composite materials for today’s high-performance, cost-conscious, and sustainability-driven industries.

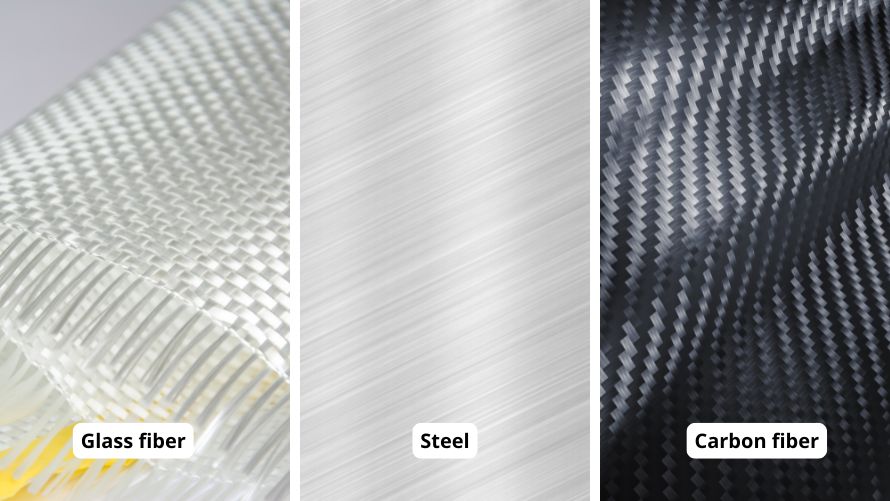

3. How Does GFRP Compare to Steel and Carbon Fiber?

When choosing the right material for performance and cost, Glass Fiber Reinforced Plastic (GFRP) stands out as a cost-effective composite—especially when compared to steel and carbon fiber.

Cost

GFRP generally costs more than traditional steel at the start. But over time, it pays off. Why? Steel needs maintenance to prevent rust and corrosion. GFRP doesn’t. That means lower lifetime costs and fewer repairs. Compared to carbon fiber, GFRP is much cheaper—making it a smart choice for projects with budget limits.

Performance

GFRP offers a high strength-to-weight ratio. It’s stronger than steel by weight, and much lighter, which reduces transport and installation costs. While carbon fiber is lighter and stronger, it’s also more brittle and significantly more expensive. GFRP strikes a good balance of durability and flexibility for most industrial needs.

Sustainability

Steel is fully recyclable, but it corrodes and requires energy-intensive production. GFRP is not as easily recycled, but it lasts longer in harsh environments. That means fewer replacements and less waste over time. In many cases, GFRP is the more eco-friendly material when total environmental impact is considered.

If you’re looking for a material that offers strong performance, lower lifetime costs, and reliable durability, GFRP is a smart alternative to both steel and more expensive composites like carbon fiber.

Read more: Fiberglass vs Carbon Fiber Reinforced Plastic: Which One Should You Use and Why?

4. Where Is Glass Fiber Reinforced Plastic Used in Real-World Projects?

Glass Fiber Reinforced Plastic (GFRP plastic) isn’t just a smart material—it’s a workhorse across industries. Its unique blend of strength, lightness, and corrosion resistance makes it ideal for demanding environments. Let’s take a closer look at how different sectors are using GFRP to solve real-world problems.

- Automotive Industry

In today’s auto world, reducing weight means improving fuel efficiency and lowering emissions. That’s why more carmakers are turning to GFRP.

A great example is the BMW i3, which uses GFRP body panels to keep the vehicle light without sacrificing strength. GFRP also helps in electric vehicles by supporting lighter battery enclosures and crash-resistant components. It offers the right mix of durability and flexibility for modern car design.

- Construction and Infrastructure

GFRP is making a big impact in construction—especially in projects that fight against corrosion. GFRP rebar, for instance, is replacing steel in bridge decks, parking structures, and tunnels. Unlike steel, it won’t rust, even in salty or humid conditions. This means longer-lasting infrastructure with lower maintenance costs.

Some bridges in North America now use GFRP as a standard to improve durability and reduce life-cycle expenses.

- Renewable Energy

The wind power industry heavily relies on composite materials like GFRP to manufacture large, lightweight, and flexible wind turbine blades. In fact, as of 2020, the U.S. had over 14.2 GW of installed wind capacity supported by blades made from GFRP.

The material’s ability to withstand extreme conditions—while keeping blades light and efficient—makes it ideal for scaling up renewable energy systems.

- Marine and Aerospace

Saltwater, moisture, and constant movement pose major challenges in marine environments. GFRP solves many of them. It’s used in boat hulls, decks, and interior panels because it resists corrosion, doesn’t rot, and stays strong over time.

In aerospace, GFRP is found in high-pressure cylinders, ducting, and secondary structures. Its lightweight profile helps reduce fuel use while maintaining high performance and safety.

5. How Is GFRP Helping Build a Greener Future?

As industries move toward greener solutions, Glass Fiber Reinforced Plastic (GFRP) is stepping up as a more sustainable choice. While it’s not yet perfect, recent innovations are helping GFRP support net-zero goals, cut waste, and move closer to the circular economy.

- Recycling GFRP: A Work in Progress

Recycling composites like GFRP isn’t easy. The challenge comes from separating the glass fibers from the polymer matrix. But new methods are changing that.

- Mechanical recycling breaks GFRP into smaller pieces that can be reused in non-structural applications like panels or insulation.

- Pyrolysis, a newer technique, uses high heat to recover clean glass fibers and possibly even reuse some of the resin content. While still in development, it shows promise for future large-scale recycling.

These recycling methods are helping reduce the environmental impact of discarded GFRP parts, especially in wind energy and construction.

- Less Waste, Smarter Manufacturing

GFRP also shines in the way it’s made. Techniques like filament winding and pultrusion allow manufacturers to create parts with minimal material waste. These precise methods mean more product, less scrap, and lower energy use. That’s a win for both the planet and the bottom line.

- A Key Player in Green Infrastructure

GFRP is being used in projects that support cleaner cities and greener energy. From corrosion-free rebar in bridges to wind turbine blades that power homes with no emissions, GFRP plays a real role in lowering the carbon footprint of entire industries. Its long lifespan also reduces the need for replacements, which saves both resources and energy.

6. Challenges and Solutions for GFRP Adoption

While Glass Fiber Reinforced Plastic (GFRP) offers many advantages, it’s not without its challenges. But the good news? Practical solutions are already in motion.

Challenge 1: Difficult Recycling of Thermoset Matrices

Most GFRP products use thermoset resins, which are tough and durable—but hard to recycle. Once cured, they can’t be melted down like thermoplastics. This has made composite recycling a big hurdle.

Solution: New methods like mechanical recycling and modified pyrolysis are making a difference. Mechanical recycling reuses GFRP as filler material in lower-grade products. Pyrolysis uses heat to separate and recover valuable glass fibers. These techniques aren’t perfect yet, but they’re improving fast and gaining support in industries like wind energy and construction.

Challenge 2: Higher Upfront Costs Than Steel

GFRP often costs more than steel at the beginning. This can be a barrier for companies with tight budgets, especially in large-scale construction projects.

Solution: Over time, GFRP can actually save money. It doesn’t corrode, lasts longer, and requires less maintenance. That means lower life-cycle costs. In many countries, government incentives and green infrastructure funding are also helping bridge the gap—especially for projects aligned with sustainability goals.

7. How to Choose Glass Fiber Reinforced Plastic for Your Project?

Thinking about using Glass Fiber Reinforced Plastic (GFRP) for your next project? Smart move—but to get the most out of it, you’ll need to choose wisely. Here’s a simple, step-by-step guide to help.

Step 1: Assess Your Project Needs

Start with the basics. What kind of loads will the material handle? Is it going to face moisture, chemicals, or high heat? And of course, what’s your budget? These factors will shape your choice of fiber type, resin, and manufacturing method.

Step 2: Pick the Right Fiber Type

GFRP isn’t one-size-fits-all.

- Use E-glass if you need solid performance at a lower cost. It’s great for general use.

- Choose S-glass for more demanding conditions. It’s stronger and more heat-resistant—ideal for aerospace or high-stress applications.

Step 3: Choose the Right Manufacturing Process

The way GFRP is made affects its performance and cost. For example:

- Pultrusion is perfect for long, straight profiles like beams or rebar.

- Filament winding works best for pipes, tanks, and pressure cylinders.

Match the process to the product, and you’ll get better results with less waste.

Step 4: Work with Trusted Suppliers

A good supplier makes all the difference. Look for companies with a proven track record—like Owens Corning, EuP, BASF, or regional specialists who understand your market. They can help with material selection, testing, and support throughout your project.

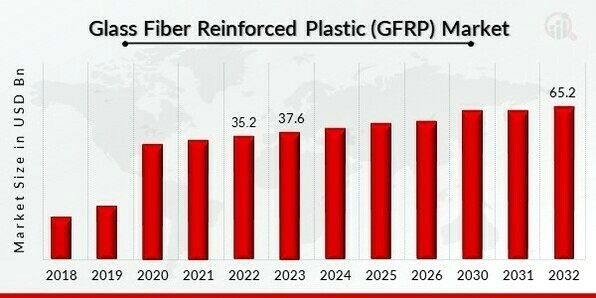

8. What’s Next for GFRP? GFRP Market Trends and Growth

The future looks bright for Glass Fiber Reinforced Plastic (GFRP). As industries push for lighter, stronger, and greener materials, GFRP is stepping into the spotlight.

According to Market Research Future, the global GFRP market is expected to grow from $40.27 billion in 2024 to $65.20 billion by 2032. That’s a clear sign that demand is rising—driven by innovation, sustainability goals, and expanding industrial use.

Recycling technologies are one major driver of this growth. More companies are investing in mechanical and thermal methods to make GFRP easier to reuse—helping it align with green technology trends and stricter environmental standards.

Another trend is the rise of hybrid composites. These combine GFRP with materials like carbon fiber or natural fibers to boost performance while keeping costs down. This makes GFRP more competitive in sectors like aerospace and high-end automotive design.

Speaking of cars, GFRP’s role in automotive lightweighting is growing fast—especially in markets like China, which aims to produce 35 million vehicles by 2025. Automakers are looking to GFRP for body panels, battery cases, and more to improve fuel efficiency and lower emissions.

In renewable energy, GFRP remains a key material in wind turbine blades and solar panel mounts. As global energy shifts toward cleaner sources, the demand for sustainable material growth will only accelerate.

Conclusion

Glass Fiber Reinforced Plastic (GFRP) is no longer just an alternative—it’s becoming a go-to material for industries seeking strength, lightness, and sustainability. From automotive and construction to wind energy and marine applications, GFRP continues to prove its value with a high strength-to-weight ratio, corrosion resistance, and long-term cost savings. As recycling technology improves and global demand for eco-friendly materials grows, GFRP’s role in the green transition will only get stronger.

At EuP Egypt, we’re proud to support this shift with a wide range of glass fiber engineering compounds tailored to diverse industry needs. Our portfolio includes:

- PC glass fiber compound for high-impact applications,

- PP glass fiber compound offering cost-effective stiffness and dimensional stability,

- ABS glass fiber compound for enhanced toughness and heat resistance,

- And high-performance options like PA6, PA66 glass fiber compounds, ideal for structural parts requiring superior mechanical strength and durability.

Whether you’re building the future of mobility, energy, or infrastructure, EuP Egypt’s advanced composite materials are engineered to deliver both performance and sustainability—helping you meet today’s challenges and tomorrow’s goals.

FAQs

1. Can GFRP be recycled?

Yes, through mechanical recycling or pyrolysis, though it’s still developing. These methods reduce waste in wind energy and construction.

2. Is GFRP eco-friendly compared to steel?

GFRP reduces waste through durability and efficient manufacturing, though recycling is harder. Steel is recyclable but requires more energy to produce.

3. Is GFRP stronger than steel?

Yes, by weight, GFRP is stronger than steel, offering similar durability with less mass, which lowers costs in transport and installation.

4. What’s the difference between E-glass and S-glass?

E-glass is cost-effective with good strength, while S-glass offers higher tensile strength and heat resistance for demanding applications.