The quest for sustainable solutions to plastic pollution has led to the development of biodegradable plastics. Key to their effectiveness are additives that accelerate the breakdown process. This list explores various types of additives, including their mechanisms, advantages, and disadvantages. By understanding these components, we can better assess the potential of biodegradable plastics in addressing environmental challenges.

1. Overview of Biodegradable Plastic

1.1. What is Biodegradable Plastic?

Biodegradable plastics encompass a range of materials. Some are derived from renewable resources like corn starch, sugarcane, and cellulose, enhancing their sustainability profile. Others are produced from petroleum-based sources but have been engineered to biodegrade. These plastics have properties similar to conventional plastic, offering comparable strength and versatility for various applications.

However, unlike traditional plastics, biodegradable plastics are designed to break down naturally when exposed to the environment. When disposed of, these innovative materials decompose into harmless minerals, water, and carbon dioxide, thanks to the action of microorganisms such as bacteria, fungi, and algae. This decomposition process significantly reduces the long-term environmental impact associated with plastic waste.

1.2. Primary Applications for Biodegradable Plastic

Biodegradable plastics find applications across a wide range of industries, offering sustainable solutions to various environmental challenges:

-

- Packaging: Biodegradable plastics are extensively used in the packaging industry for products such as food containers, shopping bags, bottles, and agricultural films, etc. These materials help reduce the accumulation of traditional plastic waste in landfills and oceans.

- Medical Field: The medical industry employs biodegradable plastics for products like sutures, drug delivery systems, and temporary implants. These materials offer the advantage of safely breaking down within the body, eliminating the need for additional surgical procedures to remove them and reducing potential complications associated with traditional, non-degradable medical implants.

- Agriculture: In agriculture, biodegradable plastics are utilized for mulch films, plant pots, and seed coatings. These products help improve soil quality and reduce the need for plastic waste management in farming practices.

- Consumer Goods: Biodegradable plastics are utilized to make a range of consumer products, such as razors, packaging materials, and toothbrushes, offering eco-friendly substitutes for commonplace items.

- Electronics: These plastics are also being explored for use in electronics, such as biodegradable casings and components, to reduce electronic waste.

- Textile: In order to promote sustainability in fashion, biodegradable plastics are utilized in the textile industry to make fibers for apparel and other fabrics

1.3. Classification of Biodegradable Plastics

Biodegradable plastics can be classified based on their origin and biodegradability. Here are the primary classifications:

-

- Polylactic Acid (PLA): Made from renewable plant-based materials that most common sources are corn starch, sugarcane, cassava, and sugar beet pulp. These plant materials are fermented to produce lactic acid, which is then converted into PLA.

- Polybutylene adipate terephthalate (PBAT): Is primarily made from petrochemical-based materials such as adipic acid, 1,4-butanediol, and terephthalic acid.

- Polybutylene Succinate (PBS): A biodegradable polyester synthesized from succinic acid and 1,4-butanediol, used in packaging and agricultural applications. While there are efforts to produce PBS entirely from renewable resources, the current industrial production process still relies on some fossil fuel-derived components

- Polycaprolactone (PCL): This petroleum-based biodegradable plastic is a synthetic aliphatic polyester with a low melting point, often used in medical devices and drug delivery systems

- Polyhydroxyalkanoates (PHA): Produced by bacterial fermentation of sugars or lipids. PHAs are used in packaging, agricultural films, and biomedical applications.

- Cellulose Acetate (CA): Derived from cellulose, which is a natural polymer obtained from plant sources such as wood pulp or cotton. It is considered biodegradable under certain conditions and is used in various applications including film, textiles, and as a component in some biodegradable plastics.

- Polyvinyl Alcohol (PVA): Made from vinyl acetate monomers through a polymerization process. PVA is notable for its water solubility and biodegradability, making it suitable for various applications such as water-soluble films, packaging, and textiles.

- Polyglycolic Acid (PGA): Made from glycolic acid – a natural substance found in various fruits and vegetables. PGA is considered a biodegradable plastic due to its ability to break down into harmless substances over time.

2. Which Additives Used For Biodegradable Plastic?

Biodegradable additives play a crucial role in accelerating the breakdown of polymers by enabling microorganisms to access and use the carbon inside polymer chains for energy. These additives were integrated into plastics in masterbatch form, typically using carrier resins such as polypropylene (PP), polyethylene terephthalate (PET), polyethylene (PE), or polystyrene (PS).

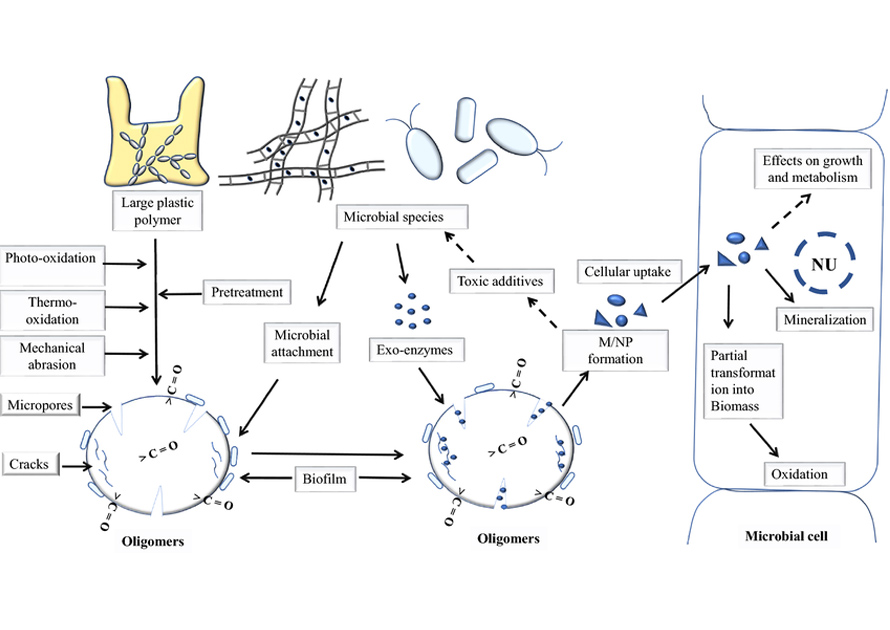

Unlike conventional synthetic plastics that resist degradation, biodegradable additives modify the chemical and physical properties of plastics, promoting quicker degradation. They attract microorganisms through quorum sensing once a biofilm forms on the plastic, facilitating the transition from mere environmental degradation, like photo-oxidation or thermal breakdown, to true biodegradable by bacteria and microorganisms. Varieties of biodegradable additives including:

2.1. Starch

Starch is a widely used biodegradable additive due to its renewable nature and low cost. Starch is a natural polymer derived from plants that offers both advantages and disadvantages as a material.

Advantages

- Starch is abundant and available year-round. It can be renewable, and biodegradable, making it an attractive option for sustainable applications.

- As a carbohydrate, starch is easily consumed by microorganisms, accelerating its breakdown in the environment.

- It can be processed into pellets and blended with plastic like PE, creating materials that degrade more quickly.

- Another wonderful advantage is starch’s ability to increase the hydrophilicity of plastics, facilitating microbial attack and degradation.

- Its low cost and availability further enhance starch additive appeal.

Disadvantages

- Starch additive is only typically used with specific synthetic plastics, limiting its versatility.

- The processing of starch can be complex and requires specific conditions to achieve desired properties

- Its highly hydrophilic feature can affect its properties and lead to exhibit lower mechanical strength compared to synthetic polymers, limiting their use in certain applications.

2.2. Bioaugmentation

Bioaugmentation additives are specialized microbial cultures or enzyme preparations that are introduced into plastic to stimulate microbial activity and accelerate the breakdown of plastic into harmless compounds. By boosting microbial activity, bioaugmentation additives significantly improve the efficiency of plastic degradation in various applications.

Advantages

- Bioaugmentation is a natural process that utilizes microorganisms to degrade plastics, minimizing the use of harmful chemicals

- This additive can be applied to various plastic types and waste streams, making it a flexible solution for plastic pollution management.

Disadvantages

- Implementing bioaugmentation additives can be expensive, increasing the overall production cost of biodegradable plastics.

- These additives may require specific environmental conditions, such as certain temperatures, pH, humidity levels, to be effective, which can limit their practicality in various settings.

- There is a risk that introduced microorganisms might be outcompeted by native microbial populations in the environment, reducing the effectiveness of the additives.

2.3. Pro-oxidant additives

Pro-oxidant additives are indeed chemical compounds specifically designed to be added to plastics to accelerate their degradation process. These compounds work by initiating oxidation reactions within the plastic, which ultimately break down the polymer chains.

Advantages

- Pro-oxidant additives significantly speed up the breakdown of plastic materials when exposed to environmental factors, reducing plastic waste accumulation.

- They facilitate the fragmentation of plastics into smaller particles, which can then more easily further degraded by microorganisms

- These pro-oxidants can be incorporated into various plastic types, offering a potential solution for a wide range of plastic products.

Disadvantages

- The effectiveness of pro-oxidant additives can depend on specific environmental factors such as UV exposure, temperature, and oxygen availability, limiting their reliability in diverse settings.

- Some pro-oxidants may release harmful substances during the degradation process, potentially contaminating the environment.

- While pro-oxidant additives accelerate the breakdown of plastics, they often result in smaller plastic particles (microplastics) rather than complete mineralization, which can still pose environmental and health risks if not further degraded.

3. Conclusion

Biodegradable plastic additives offer a promising avenue for mitigating plastic pollution as compared with synthetic polymers. Additives like starch, bioaugmentation agents, and pro-oxidant compounds each offer unique mechanisms to accelerate plastic degradation, promoting sustainability. By adopting these innovative solutions, manufacturers can create plastics that decompose more efficiently, reducing long-term pollution and contributing to a cleaner environment.

4. BiONeXT – A Biodegradable Plastic from EuP Egypt

EuP Egypt introduces BioNeXT, a revolutionary additive designed to transform traditional plastics into environmentally friendly materials. This innovative solution combines cutting-edge biodegradable polymers with proprietary additives, allowing conventional plastic products to decompose safely within landfill environments.

- BiONext 102: Is a sustainable bioplastic compound made from modified PLA and CaCO3 powder. This innovative material offers a greener alternative to traditional plastics while maintaining excellent mechanical properties like rigidity and impact strength. Ideal for injection molding applications such as cutlery and cups, others are dental toothpicks, floss, straws, etc. BiONext 102 is fully biodegradable within a year, addressing environmental concerns.

- BiONext 400: Comprising bioplastic and modified starch powder, BiONext 400 emerges as an eco-friendly alternative to traditional plastics. Able to extend food freshness and without compromising product quality through moisture retention and oxygen barrier properties. This versatile biodegradable plastic material is ideal for packaging applications.

- BiONext 500: Comprising PBAT resin and modified corn starch, BiONext 500 can biodegrade within a year. This fully functional bioplastic compound excels in packaging and blowing film applications. Its high stiffness, good elongation, and easy processing contribute to efficient production of eco-friendly products like shopping bags and food packaging.

Unlike other biodegradable alternatives that demand complex manufacturing adjustments, BiONext seamlessly integrates into existing production processes, making it a practical and cost-effective choice for businesses committed to sustainability.

With its user-friendly application and proven effectiveness, this additive empowers companies to make a positive difference. Let’s work together to create a future where plastic waste is no longer a burden but a resource for renewal. Contact us today to explore how BiONext can elevate your sustainability initiatives.