BOPP film, or Biaxially Oriented Polypropylene film, is a highly versatile material widely used across industries such as packaging and labeling. This material is well-known for its exceptional strength, transparency, and flexibility, making it an ideal choice for improving product presentation and preservation. This article will explore everything you need to know about BOPP film, its characteristics, and the manufacturing process.

1. What is BOPP Film?

BOPP (Biaxially-Oriented Polypropylene) film is a type of plastic film made by stretching polypropylene resin in two perpendicular directions. This process, called biaxial orientation, enhances the film’s strength, flexibility, and durability, making it resistant to tearing, puncturing, and other forms of damage.

BOPP film is widely used across industries, especially in packaging, labeling, and laminating. Known for its moisture barrier properties, heat sealability, and high clarity, BOPP film is a preferred choice for food packaging. It is also recyclable and compatible with polypropylene (PP) containers, making it an eco-friendly option. Its global demand continues to grow, driven by the expansion of the flexible packaging sector.

2. BOPP Film Properties

BOPP film is renowned for its versatile properties, making it an essential material in packaging industry. Here are some key properties of BOPP film:

- Density: These films have a density nearer to 0.90 g/m and hence it renders high yield at the same cost as compared to other films.

- Clarity: BOPP films have excellent gloss and high transparency that make this material ideal for showcasing products or printed content.

- High Tensile Strength: BOPP films have a high tensile strength, allowing them to endure rough handling and transit. They ensure the integrity of the packaged goods by providing great resistance to rips, abrasions, and punctures.

- Moisture and Chemical Resistance: BOPP films act as good moisture resistant barriers and have a tendency to resist pollution and harmful chemicals.

- Quick Sealing: BOPP films can be quickly and securely heat-sealed, enabling effective packaging. This function is especially helpful in the food business, where products must be sealed to ensure freshness and prevent contamination.

- Surface for Printing and Labelling: BOPP films provide a smooth, printable surface that is chemically treated and lends itself to various printing and labeling methods. They are easily customizable with top-notch graphics, branding components, and product details, increasing the packaged items’ visual appeal and marketability.

- Recyclability: BOPP film is recyclable, making it a sustainable option that reduces environmental impact.

3. Types of BOPP Films

3.1. BOPP Glossy Film

The most popular product is BOPP ordinary film, also called glossy film. It can be made waterproof by laminating glossy film on top of the non-waterproof pressure sensitive label material. The glossy film may protect the printed ink content, making the label’s surface scratch-resistant and more durable. Glossy film is frequently used in printing, food, and product packaging.

3.2. BOPP Metalized Film

Metallized BOPP films are coated with a thin layer of metal (usually aluminum) to impart a metallic appearance and enhance barrier properties. This film is frequently used for flexible packaging of snacks, candies, pharmaceuticals and toiletries, providing superior shelf life and protection against moisture and oxygen.

3.3. BOPP Holographic Film

BOPP holographic film is made up of thermoplastic. It is a visually attractive film, featuring holographic patterns. These films are available in both transparent and opaque. This type of lamination is mostly used to enhance brand packaging. It is mostly used in food, cosmetic, tobacco and alcohol packaging. It finds its applications in gift wrapping, security labels and decorative materials.

3.4. BOPP Matte Film

The principal way matte film produces its matt effect is by absorbing and reflecting optical fibers. Generally speaking, it can raise the quality of the printed surface, but the cost is quite expensive. It is frequently boxed up. Used in luxury or food packaging. Since matte film frequently lacks a heat-sealing layer, it is frequently combined with other films (such as cpp, bopet, etc.).

3.5. Printable BOPP Film

Printable BOPP film has excellent gloss and high transparency. BOPP films are known for their excellent printability. Therefore this film is an ideal solution when it comes to advertising or decorating a product. You can use both sides of treated glossy or matte BOPP films for this purpose. The printed side remains at the outer side while the inner side is joined (to the other film) with an adhesive.

3.6. BOPP Pearlescent Film

Pearlescent film usually has its own heat-sealing layer for heat-sealing. The common pearlescent film presents a white, opaque pearlescent effect, has a certain light-blocking ability, and has a protective effect on products that need to be protected from light. Additionally, the pearlescent film is often combined with other films for food and daily necessities, such as ice cream, chocolate packaging and beverage bottle labels.

4. How Is BOPP Film Made?

Step 1: Preparing raw material

The raw material system includes the process of batching, mixing and drying. The raw materials used in the production of Bopp film mainly include homopolymer polypropylene (HPP), stiffening agent, COPP, anti-adhesion agent (AB), anti-static agent (AS), lubricant and filler masterbatch.

Step 2: Extrusion

Inside the extruders, the materials are melted and brought to 200-230°C and then conveyed through the extrusion head, where they emerge in the form of foil.

Step 3: The foil cooling

The foil is then placed in direct contact with a cooled cylinder and immersed in a water bath to quench the melt.

Step 4: Machine direction orientation (MDO)

The film then passes over a series of rollers, which increase the temperature and prearrange it to stretch longitudinally (machine direction). The stretching is achieved by passing the foil between the rollers that run at increasing speeds. As a rule, the foil is stretched up to five times the initial length and, at this stage the polymer chains are aligned.

This stage allows the enhancement of the film’s mechanical properties, also, the thickness is reduced up to five times. After stretching, the film is heated once again in order to neutralize the stress accumulated during the stretching (annealing phase).

Step 5: Transverse direction orientation (TDO)

Once out of the longitudinal stretching zone, the film is gripped on both edges by a fast-moving chain of metal jaws (tenter clips). In the tenter, the film goes into an oven, where its temperature rises before being stretched transversely by the diverging rails (i.e. stretching in transverse direction up to 9 times its original width).

At this stage, the macromolecules align, this time in transverse direction, enhancing the film mechanical properties and reducing the thickness up to 9 times. Following the stretching stage, the chain and the film converge, so that the film neutralizes the stress accumulated during the stretching (annealing phase).

Step 6: Thickness measurement and flame treatment

The film reaches a new processing stage where it takes the automatic measurement of the thickness (along the entire width). Afterward, one of the faces is subject to the flame or corona treatment to make the film suitable for the following conversion activities, namely, modifying the surface, that is intended to anchor materials such as ink (printing process), adhesive (lamination process), or metal (metallization process).

Step 7: Reel winding

BOPP film is wrapped around a reel and is slit according to the requested dimensions.

5. Applications and Uses of BOPP Films

5.1. Food and Beverage Packaging

BOPP film is widely used in the packaging of food and beverage products due to its high strength and durability, as well as its moisture resistance. BOPP film can be used to create a variety of different types of packaging, including stand-up pouches, vacuum pouches, and side-gusseted bags. These packaging types help protect food and beverage products from damage during transportation and storage.

5.2. Labeling

BOPP’s smooth texture allows for precise printing of barcodes, intricate designs, and vibrant logos, making it ideal for labels and stationery. Its stiffness ensures optimal stability during high-speed labeling processes, minimizing tears and wrinkles.

5.3. Industrial Applications

BOPP films find use in various industrial settings. Their strength and moisture resistance make them suitable for wrapping machinery parts, bundling products, and creating protective layers.

5.4. Textiles

BOPP films are used as backing materials for fabrics and tapes, providing structure and stability. It is also often used for textile packaging. Its transparency allows distributors and manufacturers to correctly identify garments packed in bulk. Thick garments such as blankets require packaging with high seal strength which is easily attained with BOPP films.

5.5. Stationery and Office Supplies

BOPP films are used to create clear pockets in binders, dividers in notebooks, and laminating pouches for documents. It is also used to create adhesive tapes and clear packaging that protects notebooks and pens from damage.

5.6. Medical Packaging

BOPP film is also used in the packaging of medical products and devices, including bags, pouches, and blister packs. These types of packaging help to protect medical products and devices from damage, while also allowing for easy identification of the contents.

6. Benefits of Using BOPP Film

- Shelf life extension: The BOPP film offers the best moisture barrier of all the regularly used plastic films, and its metalized version offers the best oxygen barrier to the goods. These two characteristics of BOPP films are crucial for food packaging because they increase product shelf life and decrease food waste.

- Product quality: BOPP film’s consistent quality ensures reliable sealing and excellent performance during the packaging process. It works well with various packaging machines and creates strong, dependable seals at different temperatures. These features make it a practical choice for many manufacturers.

- Aesthetic: BOPP film stands out with its crystal-clear transparency. Products packaged in clear BOPP film are easily visible to customers. The film also accepts high-quality printing, allowing for attractive designs and branding. For products requiring opacity, white BOPP film provides excellent coverage while maintaining an appealing look.

- Cost-effectiveness: BOPP film is an economical choice for packaging and labeling, as it is readily available, easy to convert, and has a low cost per square foot compared to other materials. This makes it an ideal choice for businesses looking to balance quality and cost in their packaging solutions.

7. BOPP Film Market Analysis

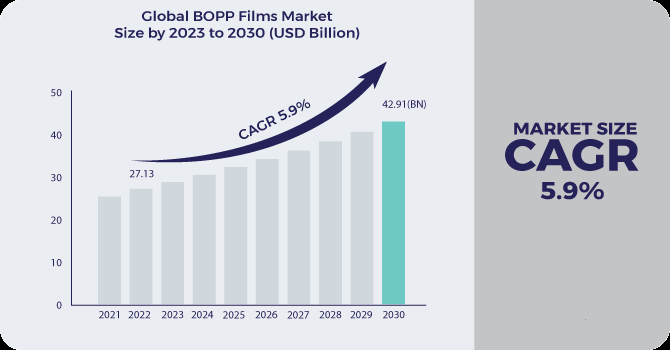

The BOPP Films Market is expected to increase at a CAGR of 5.9% from 2024 to 2031 from USD 28.7 billion in 2023 to USD 45.5 billion in 2031. The packaging industry uses biaxially oriented polypropylene films, which could eventually replace metal cans and cartons.

The demand for Biaxially oriented polypropylene films is steadily expanding as consumers seek more convenient solutions and options that are easier to transport. Pressure-sensitive types, stationery, labels, metalizing, consumer products, and other applications all use biaxially oriented polypropylene films. As the food and beverage industry increases around the world, it is recognised as the primary end-user market for BOPP films.

Due to increased expansion in end-user sectors such as food and drinks, medical, and personal care, the Asia-Pacific region is predicted to have a higher market growth rate in the Biaxially oriented Polypropylene films industry.

Packaging and manufacturing industries are also growing in the Asia-Pacific area, which is a major growth driver for biaxially oriented polypropylene films.

Furthermore, the Asia-Pacific area is experiencing increased demand in the retail and e-commerce sectors, where Biaxially Oriented Polypropylene films are widely used.

8. Is BOPP film recyclable?

Yes, the Biaxially oriented polypropylene film is recyclable. While recycling, it doesn’t degrade as much as other films. BOPP films can be easily recycled by mixing them in a polypropylene recycling stream. Almost every product made from polypropylene (including BOPP) can be recycled into polymer pallets that can be used for a variety of industrial and commercial applications.

9. Conclusion

In conclusion, BOPP films continue to evolve to meet the dynamic demands of the packaging industry, offering an extensive array of types, applications, and innovative solutions. From plain films to high-barrier and bio-based alternatives, BOPP films play a pivotal role in enhancing product visibility, shelf life, and sustainability across various sectors.

EuP Egypt, a key member of the EuP Group, is a global leader in filler masterbatch production with over 17 years of expertise. The company specializes in high-quality products like bioplastic compounds, color masterbatch, additives, engineering plastic compounds, filler masterbatch and bio filler. As a trusted partner, we support manufacturers with reliable and cost-effective plastic raw materials, solidifying their position in the plastics industry.