Using masterbatch in plastic bottle production is an effective way to achieve vibrant colors, enhance properties, and reduce costs. Let’s find out!

Manufacturers all know that every cost-saving measure counts in plastic bottle production. One of the most effective ways is using masterbatch.

This concentrated mixture not only enhances the quality of your plastic bottles but also significantly reduces material and processing expenses.

This article will explain how this substance can help you achieve both quality and economic purposes and suggest a reliable partner to assist you in finding the most suitable masterbatch. Follow along!

1. What is Masterbatch in Plastic Bottle Production?

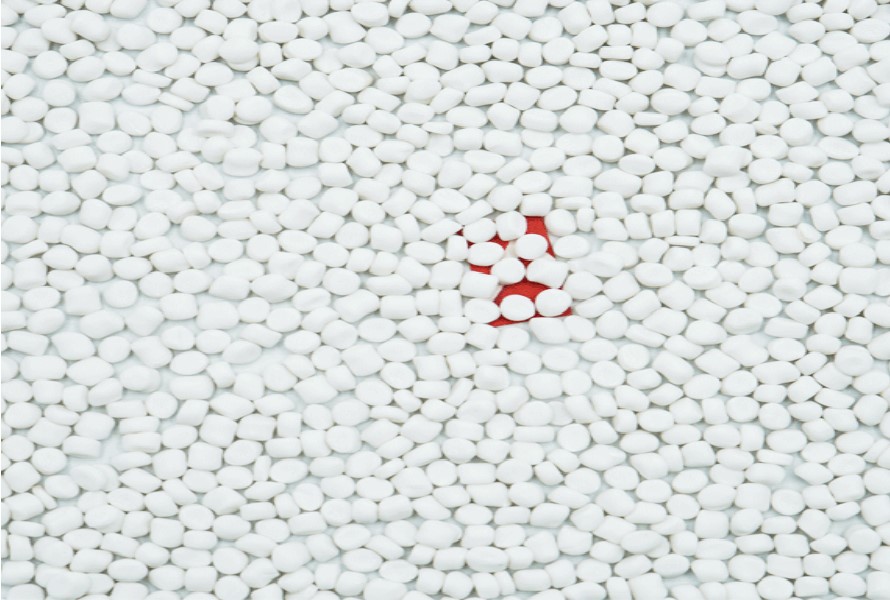

Masterbatch, which is used in plastic bottle production, combines pigments, additives, or other materials into a polymer resin. The purpose of this substance is to acquire certain features, such as color, UV resistance, or increased durability. Manufacturers can easily add this material to their manufacturing process.

In plastic bottle production, masterbatch is usually blended with the base polymer resin (such as PET, HDPE, or PP), and all of them go through the injection molding or extrusion process. During these processes, the solution is uniformly dispersed, guaranteeing the consistent desired properties for plastic bottles.

Read more:

- Raw Materials of Plastic Bottles: Exploring the Different Types of Plastic Used

- How Plastic Bottles Are Made: A Complete Guide to the Manufacturing Process

2. Types of Masterbatch for Plastic Bottles

Here are 3 most popular types of masterbatch used in plastic bottle production:

-

Color Masterbatch

This masterbatch type consists of a carrier resin and highly concentrated pigments, offering a plastic bottle uniform and vibrant color. It helps manufacturers achieve their desired appearance and visual appeal for their products. The pigment concentration in color masterbatch for plastic bottles is uniformly loaded, typically between 40-65%, but can be adjusted to 15-80% in some cases.

-

Filler Masterbatch

Filler masterbatch for plastic bottles is a material used to alter the physical and chemical characteristics of the products. It consists of calcium carbonate, talc, and other inorganic fillers compatible with the base polymer. These masterbatches are available in a variety of concentrations and compositions. It’s usually used to substitute less expensive, inert fillers for some of the primary components to lower manufacturing costs.

-

Additive Masterbatch

Additive masterbatch is a substance commonly used in plastic bottle production to enhance the product’s quality. Plastic bottle manufacturers usually buy this material in pellet form from masterbatch manufacturers and add it to the raw polymer. Common traits that additive masterbatch for plastic bottles usually provide include UV stabilizers, anti-static, anti-fog, and flame retardants.

3. How Masterbatch Reduces Plastic Bottle Production Costs

Using masterbatch in plastic bottle production is a budget-saving solution for businesses since only a small amount of this substance needs to be added to the basic polymer resin to achieve the desired characteristics. Masterbatches reduce plastic bottle production cost by removing the need for manufacturers to purchase or process vast quantities of raw materials separately.

By using the proper additives, colors, and components in the exact amounts, masterbatch facilitates the manufacturing process and saves time on preparation, mixing, and quality assurance. Thus, the production process is simpler and faster. Without masterbatch, manufacturers may require distinct steps to guarantee that additives are distributed uniformly.

Another benefit of using masterbatch in plastic bottle production is reduced energy consumption. Some additives can speed up polymer production, cutting down on energy use and cycle times. For example, certain additives can reduce the melting point of resin, which lowers the energy required to heat plastic during injection molding or extrusion.

Besides, masterbatch is pre-mixed and simple to use, minimizing mistakes and uneven mixing. Therefore, it can lower waste in the plastic bottle production process. It also lessens the possibility of discarding ingredients that have been incorrectly blended or combined. Thus, masterbatch guarantees a precise, constant mix and lowers waste and expenses of useless products.

Read more: Plastic Bottle Production Cost: A Detailed Analysis

4. EuP Egypt’s Masterbatch Solutions

EuP Egypt is a reliable partner for many manufacturers in plastic bottle production. We provide unique, cost-effective solutions to help businesses optimize production costs and improve their competitiveness in the market.

Product range

With a wide range of masterbatch choices, customers can easily choose a suitable one for their plastic items. EuP Egypt can also customize options so that our clients can meet the final product requirements.

We have:

- Color masterbatch: Our color masterbatch is ideal for industrial processes, including extrusion, injection molding, and film blowing, since it offers excellent dispersion, a steady color tone, and exceptional heat resistance. In comparison to pigment powder, it also lowers dust, air pollution, and loss rate, increasing processing effectiveness and reducing manufacturing costs and time. Depending on the needs of the final product, EuP Egypt offers a variety of colors as well as specialty products with a range of effects.

- Filler masterbatch: It’s a cost-effective solution to improve the hardness and impact resistance of final goods, as well as printability, surface quality, and production stability. Because of its high thermal conductivity, it also conserves energy during processing. Our filler masterbatch is suitable for many different applications, including PVC pipe manufacturing, blow molding, injection molding, packaging, plastic frames, and doors.

- Additives: EuP Egypt is a reputable supplier of plastic additives. Our products improve plastic’s physicochemical resistance to the environment and lessen friction between the material and production equipment, extending its lifespan and durability. We offer a list of additives, including deodorizing/odor-removing additives, desiccant additives, flame retardant additives, anti-fog additives, anti-aging additives, processing aid additives, anti-static additives, and anti-UV additives.

Quality standard

In masterbatch manufacturing, EuP Egypt is dedicated to upholding the highest standards of quality. To ensure peak performance, we employ premium raw materials from reliable vendors. EuP Egypt carries out strict testing, such as color consistency tests, additive performance tests, and polymer compatibility tests, to guarantee that our products satisfy various requirements. Our masterbatches for use in food packaging also adhere to the FDA.

Technical support

EuP Egypt has a modern factory system in 6 provinces in Vietnam and 1 in Egypt to produce top-notch products. Our factories use cutting-edge technology, such as modern machinery like extruders, blown film machines, and injection molding machines, in addition to common testing devices like impact, tensile strength, and plastic thermal deformation testing machines, to guarantee your quality. We also focus on a lab system with the latest equipment to develop new materials. Our professional and passionate team is always devoted to bringing the best quality products to customers.

Success stories

EuP Egypt is a trustworthy partner of thousands of factories in more than 90 countries worldwide. Our annual capacity reaches approximately 0.8 million tons, allowing us to meet bulk orders from all over the world. We are also on the list of Top 500 Fastest Growing Enterprises. Cooperating with us will open a gateway for your business to grow.

5. Choosing the Right Masterbatch for Your Application

Choosing the proper masterbatch for your plastic bottle production will ensure the quality and efficiency of your application. Here are a few things you should consider before making a decision:

- Material compatibility: The masterbatch of your choice should be compatible with the base polymer of your product. Confirm with the suppliers if their masterbatch is suitable for your process, including extrusion and injection molding.

- Desired properties: What the final product requires will affect your decision. If you target a specific color, a high-quality color masterbatch can provide a consistent desired shade. Meanwhile, using additive masterbatch is helpful in achieving particular properties like UV resistance or flame retardancy.

- Processing temperature: Keep in mind the importance of temperature stability. If the process requires high temperature, ensure you choose the right masterbatch to withstand it without affecting the functionality.

- Supplier’s reputation: Quality assurance from reliable suppliers, such as EuP Egypt, can guarantee you gain benefit from an appropriate masterbatch for your plastic bottle production. They usually offer sample testing and custom solutions to meet your requirements.

6. Get Started with EuP Egypt’s Masterbatch Solutions

Whenever you look for a masterbatch for plastic bottles, remember EuP Egypt.

Here’s how we help optimize your products and processes.

- Consultation process

We always take a collaborative approach to comprehend your unique demands and give the finest solution. Based on your product requirements, we’ll carry out a needs assessment, compiling comprehensive data on your specifications, including the kind of plastic to be used, the needed qualities, and any environmental or legal requirements. We also offer sample testing.

Once you choose your option, EuP Egypt will work with you to make an order, go over lead times, pricing, and any necessary follow-up assistance until the order is complete. In order to make sure the masterbatch keeps meeting your needs (including troubleshooting, production optimization, or scaling up), we also offer continuous technical assistance.

- Custom solutions

EuP Egypt provides customized masterbatch solutions that are suited to your manufacturing process and meet your unique challenges. We offer precise masterbatch color-matching services so that your products can achieve the desired colors and effects. Additive masterbatch customization is also available, giving tailored properties such as enhanced durability, UV protection, and flame retardancy. EuP Egypt also creates food-grade and biodegradable solutions if you need one for your product.

- Contact information

Start exploring our masterbatch solutions for your plastic bottle production through these channels:

-

- Office: City Light Towers, 1st Makram Ebeid Street, Cairo, Egypt

- Factory: CPC Sadat Industrial Park, El Sadat City, Menofia, Egypt

- Phone: (+20)1220165445

- Email: info@eupegypt.com

- Website: https://eupegypt.com/

Conclusion

Masterbatch plays an important role in plastic bottle production as it can improve the final product’s appearance, quality, and performance. This material is also a strategic tool to cut down production costs. With all of its benefits, manufacturers should not overlook this option and choose the right masterbatch from trustworthy suppliers for significant benefits.