Plastics and rubber are ubiquitous materials found in countless products we use daily. Although they may appear similar, they have distinct properties and applications. Understanding these differences is crucial for choosing the right material for specific uses.

1. Understanding Plastics and Rubber

Plastics and rubber are fundamental materials that play vital roles in numerous applications across various industries.

Plastics are synthetic materials made from long chains of polymers, known for their versatility and durability. Meanwhile, rubber is an elastic material, sourced from natural or synthetic origins, and is defined by its ability to stretch and return to its original shape.

2. Key Differences Between Plastics and Rubber

Here’s a table summarizing the key differences between plastics and rubber:

| Plastics | Rubber | |

| Chemical composition | Synthetic polymers | Natural or synthetic elastomers |

| Elasticity and flexibility | Flexible, less elastic; can be brittle | Highly elastic; returns to shape |

| Strength and durability | Generally strong and durable | Durable in dynamic situations |

| Resistance to heat and chemicals | Varies; some heat-resistant | Better chemical resistance; less heat-resistant |

| Manufacturing processes | Injection molding, extrusion, blow molding | Molding and extrusion; require curing |

2.1. Chemical Composition and Structure

Plastics are primarily made from synthetic polymers derived from petrochemicals. These polymers have a long-chain molecular structure that can be manipulated during processing.

Meanwhile, rubber consists of elastomers, which can be natural or synthetic. The molecular structure of rubber allows for cross-linking, giving it unique elastic properties.

2.2. Elasticity and Flexibility

Plastics and rubber differ significantly in their elasticity and flexibility.

Rubber has higher elasticity, allowing it to stretch significantly and return to its original shape without permanent deformation. In contrast, while plastics can also be flexible, they generally lack the same level of elasticity. Some plastics may become brittle under stress, particularly at lower temperatures, limiting their flexibility compared to rubber.

2.3. Strength and Durability

When comparing plastics and rubber, plastics are typically stronger and more durable. Although rubber is durable and offers flexibility and resilience, it may not match the strength of plastics in static applications. However, rubber excels in dynamic situations where flexibility and shock absorption are essential.

2.4. Resistance to Heat and Chemicals

When comparing plastics and rubber, their resistance to heat and chemicals varies.

Plastics exhibit varying degrees of resistance to heat and chemicals, depending on their type. Some, like polycarbonate, can withstand high temperatures, while others may deform or degrade under heat. Meanwhile, rubber generally has lower heat resistance but is often better at resisting chemicals, particularly oils and solvents.

Read more: Temperature ranges for different plastic materials

2.5. Manufacturing Processes

The manufacturing processes for plastics and rubber differ significantly.

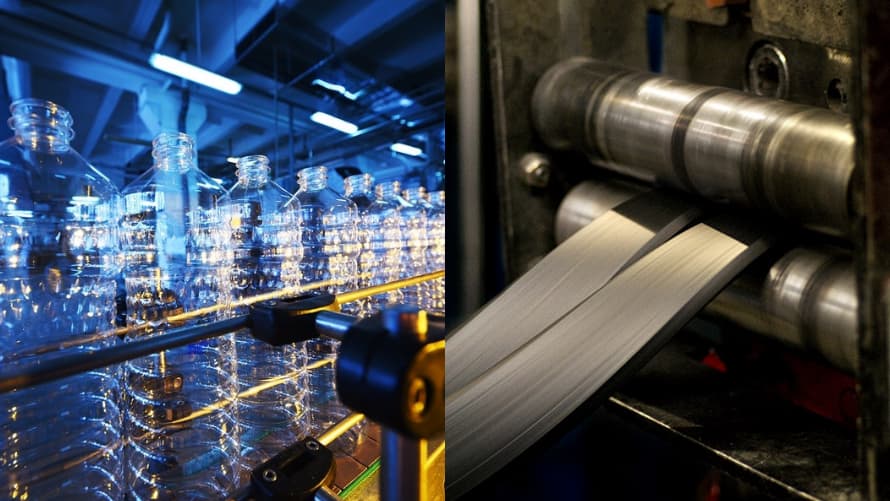

Plastics are commonly processed through methods such as injection molding, extrusion, and blow molding, allowing for precise shapes and mass production. On the other hand, rubber is often processed through molding and extrusion as well, but it typically requires a curing process (vulcanization) to enhance its elasticity and strength.

3. Common Applications of Plastics and Rubber

3.1. Plastic Applications

Plastics are incredibly versatile and are used in a wide range of applications due to their lightweight and durable nature. Some common applications include:

- Packaging: Plastics are the dominant material for packaging, used in items like bottles, containers, and food wraps. They provide excellent barrier properties, keeping products fresh and protected from contamination.

- Consumer goods: Everyday items such as toys, kitchen utensils, and household goods are often made from various types of plastics, which can be molded into intricate shapes and designs.

- Automotive: Plastics play a crucial role in the automotive industry, used for dashboards, bumpers, and various interior components. They help reduce vehicle weight, improving fuel efficiency.

- Medical devices: The medical field relies heavily on plastics for syringes, tubing, and disposable instruments. Their ability to be sterilized and molded into precise shapes makes them ideal for hygiene-sensitive applications.

- Electronics: Plastics are used in casings, insulators, and circuit boards, providing protection and insulation for electronic components while allowing for lightweight designs.

3.2. Rubber Applications

Rubber is also extensively used across various industries due to its unique properties, particularly its elasticity and durability. Key applications include:

- Tires: Rubber is essential for manufacturing tires for vehicles, bicycles, and heavy machinery. Its flexibility and grip provide safety and performance on various surfaces.

- Seals and gaskets: Rubber is commonly used in seals and gaskets for plumbing, automotive, and industrial applications. These components help prevent leaks and ensure a tight fit between parts.

- Footwear: Rubber is widely used in the production of shoe soles and insoles, offering comfort, durability, and traction. Its cushioning properties enhance the wearer’s experience.

- Industrial hoses: Rubber hoses are used for fluid transfer in industries such as agriculture, construction, and manufacturing. They are designed to withstand high pressure and resist wear.

- Sports equipment: Rubber is integral to many sports products, including balls, mats, and grips. Its elasticity and shock-absorbing qualities enhance performance and safety in various sports activities.

4. Advantages and Disadvantages of Plastics and Rubber

Both plastics and rubber are widely used materials with unique properties that make them suitable for various applications. Below, we explore the strengths and weaknesses of each material:

| Plastics | Rubber | |

| Advantages |

|

|

| Disadvantages |

|

|

5. Environmental Impact

The environmental impact of plastic and rubber is considerable.

Plastic production contributes to greenhouse gas emissions and pollution, with discarded plastic persisting in the environment for hundreds of years and harming wildlife. While some plastics can be recycled, many items are not due to contamination.

Rubber, including natural and synthetic forms, also poses challenges. Natural rubber can lead to deforestation if harvested unsustainably, while synthetic rubber has high emissions. Rubber products like tires take a long time to decompose, complicating waste management.

Therefore, both materials require effective management and recycling strategies to mitigate their environmental impact.

Read more: How Long Does It Take For Plastic To Decompose In The Ocean? Science Reveals The Truth!

6. Conclusion

Understanding the differences between plastics and rubber is vital for making informed material choices. Each material has unique properties that make it suitable for specific applications, and being aware of their advantages, disadvantages, and environmental impacts can lead to better decision-making in manufacturing and consumer choices.

EuP Egypt is a reputable company that manufactures premium plastic compounds and additives. Our products include bioplastic compound, engineering plastic compound, color masterbatches, plastic additives, filler masterbatches, and biofillers. All designed to enhance the performance, durability, and aesthetics of plastic materials across various applications.

Contact us for more assistance!