Plastic waste is a growing global challenge, overwhelming landfills and polluting ecosystems. But there’s good news—innovative recycling technologies and methods can transform this problem into an opportunity for sustainability. In this article, we’ll explore plastic recycling technologies, essential equipment, and step-by-step processing methods that make recycling more efficient and effective. Keep reading to learn more!

1. Plastic recycling overview

Plastic recycling is the process of collecting plastic waste and turning it into new useful products. Instead of throwing plastics away, we clean, sort, and process them to make new items. This simple but powerful process helps us use plastic materials again and again, reducing the need to make new plastic from raw materials.

Recycling plastics is vital for our planet’s health. When we recycle, we:

- Save energy – making products from recycled plastic uses less energy than making new plastic

- Reduce pollution – less plastic ends up in oceans, rivers, and landfills

- Conserve resources – we use fewer fossil fuels to make new plastic

- Create jobs – recycling centers provide work opportunities in local communities

Every plastic bottle or container you recycle helps build a more sustainable future for everyone.

Plastic waste creates serious problems worldwide. In Africa, these challenges include:

- Limited collection systems – many areas lack regular waste pickup

- Mixed waste – different types of plastics often get mixed together, making recycling harder

- Contamination – food residue and dirt can make plastics difficult to recycle

- Lack of processing facilities – many regions don’t have enough recycling equipment

Despite these challenges, plastic recycling offers a practical solution. With the right knowledge and tools, plastic manufacturers and technicians can turn waste into valuable resources while protecting the environment.

2. Types of Plastic Recycling Technologies

2.1. Mechanical Recycling: The Traditional Approach

Mechanical recycling is the most common method of recycling plastics. It involves collecting, cleaning, shredding, and melting plastic waste to create new products.

This process works best for clean and sorted plastics, such as bottles and containers. While it is simple and cost-effective, it has limitations, as it cannot handle heavily contaminated or mixed plastics.

2.2. Chemical Recycling: Breaking Down Plastics at the Molecular Level

Chemical recycling is a more advanced method. It breaks plastics down into their basic chemical building blocks, which can then be used to make new plastics.

This method is useful for recycling mixed or dirty plastics that cannot be processed mechanically. Although it is more expensive, it offers a way to recycle plastics that would otherwise go to waste.

2.3. Dissolution Recycling: Purifying Polymers for Reuse

Dissolution recycling focuses on purifying plastics without breaking them down completely. In this process, plastics are dissolved in special solvents to remove impurities like dirt, dyes, or additives. The purified plastic can then be reused to make high-quality products.

This method is ideal for recycling specific types of plastics that need to maintain their original properties.

2.4. Organic Recycling: Biodegradable Plastics and Composting

Organic recycling is used for biodegradable plastics. These plastics are designed to break down naturally in composting systems. Instead of being melted or chemically processed, they decompose into organic matter, which can be used as fertilizer.

This method is still developing and works best for specific types of plastics labeled as biodegradable.

2.5. Advanced Recycling Innovations: AI, Robotics, and IoT Integration

New technologies like artificial intelligence (AI), robotics, and the Internet of Things (IoT) are transforming plastic recycling. AI-powered sorting machines can quickly identify and separate different types of plastics, improving efficiency.

Robotics can handle tasks like sorting and cleaning, while IoT systems can track and monitor recycling processes in real time. These innovations make recycling faster, more accurate, and more cost-effective.

By understanding these technologies, plastic manufacturers and technicians can choose the best methods to recycle waste and create valuable products.

3. Essential Equipment for Plastic Recycling

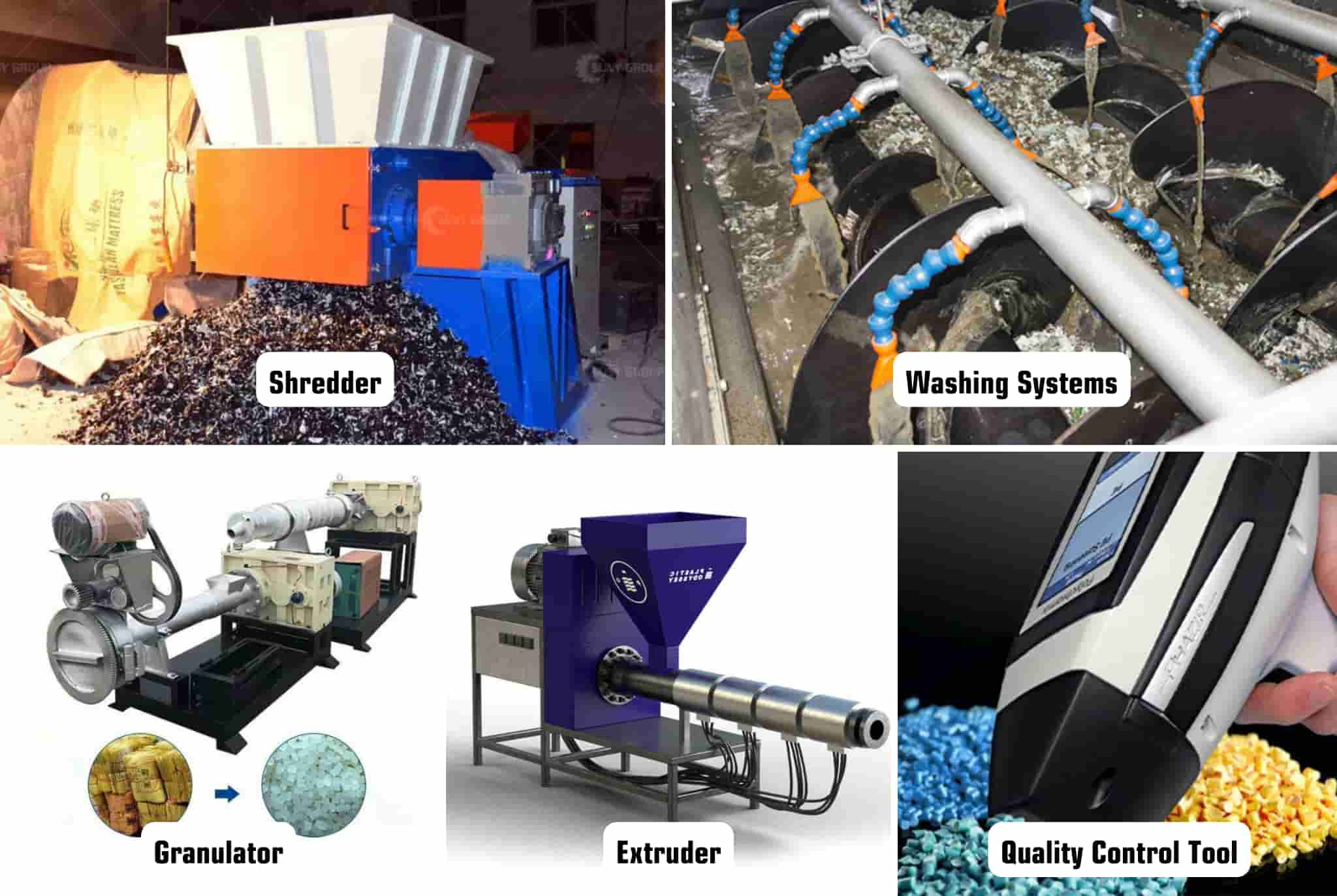

Shredders

Shredders are the first step in recycling plastic. They cut large plastic items, like bottles, containers, or pipes, into smaller pieces. This makes it easier to handle and process the plastic in the next steps.

Shredders come in different sizes, so you can choose one that fits the amount of plastic you need to recycle. A good shredder saves time and reduces the effort needed to prepare plastic waste.

Washing Systems

Washing systems clean plastic waste by removing dirt, labels, and leftover food or liquids. Clean plastic is important because dirty plastic can ruin the recycling process. Washing systems use water and sometimes detergents to ensure the plastic is ready for the next stage.

For example, PET bottles need to be washed thoroughly before they can be recycled into new products like fibers or containers.

Granulators and Pelletizers

Granulators and pelletizers turn shredded plastic into small, uniform pieces. Granulators grind the plastic into flakes, while pelletizers melt the flakes and shape them into small pellets. These pellets are easy to transport and can be used directly by manufacturers to make new plastic products. This step is essential for creating high-quality recycled plastic that can compete with new plastic.

Extruders

Extruders are machines that melt plastic pellets and shape them into new products. The melted plastic is pushed through a mold to create items like pipes, sheets, or packaging materials.

Extruders are versatile and can be used to make a wide range of products. They are a key part of turning recycled plastic into something useful again.

Quality Control Tools

Quality control tools check the recycled plastic to make sure it meets industry standards. These tools test for things like strength, color, and purity.

For example, spectrometers can check if the plastic is free from unwanted materials.

By using the right equipment, plastic manufacturers and technicians can recycle plastic waste efficiently and produce materials that are ready for reuse. Starting with shredders and washing systems is a good first step, and you can add more advanced equipment like extruders and quality control tools as your recycling operation grows.

4. Step-by-Step Plastic Recycling Process

Step 1: Collection and Sorting

The plastic recycling process begins with collecting and sorting plastic waste. This first step determines the quality of your final product.

For collection, you can:

- Partner with local businesses that generate plastic waste

- Set up collection points in communities

- Work with existing waste collectors

- Organize clean-up events at beaches or public areas

Once collected, sorting is crucial. Different types of plastics cannot be recycled together. Look for the recycling symbol (a number inside a triangle) on plastic items:

- #1 (PET) – Water bottles, soda bottles

- #2 (HDPE) – Milk jugs, detergent bottles

- #3 (PVC) – Pipes, window frames

- #4 (LDPE) – Plastic bags, squeeze bottles

- #5 (PP) – Bottle caps, food containers

- #6 (PS) – Foam cups, food trays

- #7 – All other plastics

Start by focusing on the most common and valuable types like PET (#1) and HDPE (#2). You can sort manually using tables where workers separate different plastics, or invest in basic sorting equipment as your operation grows.

Step 2: Cleaning and Washing

After sorting, plastics need to be cleaned to remove contaminants like labels, glue, food residue, dirt, and oils

A basic washing system includes:

- Pre-wash tank to remove loose dirt

- Main wash tank with soap or cleaning solution

- Rinse tank with clean water

- Drying area or equipment

For small operations, you can start with simple tanks and manual washing. As your business grows, you can invest in friction washers or floating tanks to improve efficiency.

Remember to manage your wastewater responsibly. Simple filtration systems can help you reuse water and reduce environmental impact.

Step 3: Shredding and Granulating

After washing, plastics need to be cut into small, uniform pieces. This happens in two stages:

First, shredding breaks down large items:

- Feed clean plastic items into the shredder

- The rotating blades cut plastic into rough flakes (2-4 cm)

- These flakes fall through a screen at the bottom

Next, granulating creates smaller, more uniform pieces:

- Shredded flakes enter the granulator

- High-speed cutting blades reduce them to tiny pieces (3-5 mm)

- A screen ensures all pieces are the right size

Maintaining your equipment is essential. Keep blades sharp, clean machines daily, and check for hard objects like metal that could damage the blades.

Step 4: Melting and Extrusion

Now it’s time to transform your plastic flakes into a form manufacturers can use. This typically happens through extrusion:

- Plastic flakes enter the extruder’s hopper

- A rotating screw pushes the plastic forward while heating elements melt it

- Filters remove any remaining impurities

- The melted plastic passes through a die that shapes it

- Water baths cool the plastic as it exits

- A pelletizer cuts the cooled plastic strand into small pellets

Temperature control is critical during this process. Each type of plastic melts at a different temperature:

- PET (#1): 260-280°C

- HDPE (#2): 200-240°C

- PP (#5): 230-260°C

Running at the wrong temperature can burn the plastic or leave it partially unmelted. Start with small batches until you find the right settings for your equipment and materials.

Read more: Temperature ranges for different plastic materials

Step 5: Final Quality Checks and Packaging

Before selling your recycled plastic, it’s important to perform quality checks to ensure it meets customer standards. This includes visually inspecting the pellets for contamination or color inconsistencies, testing for moisture levels, and checking the melt flow to ensure the plastic behaves correctly when heated.

Once the quality is confirmed, package the pellets in moisture-proof bags or containers, clearly label them with the type of plastic, and ensure the packaging is professional to build customer trust.

By following these steps carefully, even a small recycling operation can produce quality recycled plastic that manufacturers will want to buy. Start simple, focus on quality, and expand your process as you gain experience and market demand grows.

5. Challenges in Plastic Recycling

Plastic recycling faces several challenges that can make the process difficult. Contamination is a major issue, as food residue, dirt, and mixed plastics reduce the quality of recycled materials.

Advanced plastic recycling technologies, like chemical recycling, are expensive and often out of reach for smaller businesses.

Many regions also lack the infrastructure needed for chemical or organic recycling, limiting options for handling certain types of plastics.

Additionally, recycled plastics often compete with cheaper virgin plastics, making it harder to sell recycled products at a profit.

To learn more about common problems when working with recycled plastics and how to solve them, please read: Top 5 Common Problems When Working with Recycled Plastics

6. Conclusion

Plastic recycling is a powerful solution to reduce waste, conserve resources, and protect the environment. By understanding the technologies, equipment, and processes involved, businesses can turn plastic waste into valuable materials.

While challenges like contamination and high costs exist, advancements in recycling methods and equipment offer hope for a sustainable future.

When it comes to overcoming the challenges of working with recycled plastics, EuP Egypt stands out as a trusted partner for plastic manufacturers across Africa. With over 17 years of experience and a strong presence in more than 95 countries, EuP Egypt specializes in providing filler masterbatch, color masterbatch, and additive masterbatch solutions that help manufacturers improve product performance, reduce costs, and promote sustainability.

Contact EuP Egypt today to learn how we can help your business thrive!